LUBRICAC

-

Upload

aaron-robinson -

Category

Documents

-

view

214 -

download

1

description

Transcript of LUBRICAC

-

CURSO DE LUBRICACION1Teora de lubricacin

2Lubricacin con aceite

3Lubricacin con grasa

-

Funcin del lubricanteSeparar las superficies de rodadura - eliminar el desgaste - reducir la friccin

Proteger al rodamiento - de la corrosin - de la contaminacin

-

El desempeo del lubricante la capa mide 1/100 del espesor de una hoja de papel ! soporta la presin que ejercen 10 autos en una ua !los elementos rodantes corren en una delgada capa de lubricanteNo hay contacto metal-metal

-

Viscosidad del aceite VISCOSIDAD = "resistencia a fluir" de un lquidoalta viscosidad ~1200 cSt @ 20Cbaja viscosidad 1 cSt @ 20Cbaja viscosidad:

+ menor friccin- capa lubricante delgadaalta viscosidad:

+ capa lubricante gruesa- mayor friccin La viscosidad del aceite base cambia con la temperatura !

-

Importancia de la viscosidad del aceite base:la temperatura la velocidad de giro la cargaEl espesor de la capa lubricante en el rodamiento depende de:La viscosidad del aceite base es la principal herramienta para ajustar el espesor de la capa lubricante

-

Grasa o aceite ? Grasa: Aceite:

+ instalacin sencilla (barata)+ enfriamiento adicional+Proteccin adicional+ se puede filtrar y analizar vs humedad, contaminacin)80% de los rodamientos se lubrican con grasa

-

Tipos de aceites base (1):Minerales (~90%) aplicaciones standar Sintticos (~10%) propiedades especiales, muy caros Naturales (~ 1%) compatibles con alimentos, biodegradablesLubricacin con aceite

-

Qu es la grasa ?La grasa es un aceite "ESPESADO" No es:-un aceite muy viscoso -un aceite slidopiensa en una esponja

-

Aceite base(70-95 %)Espesante(5-30 %)Aditivos De qu est hecha la grasa ?Grasa =++

-

Tipos de espesantes (2)Jabn Litioestndar, efectivoMetlicoCalcioresistente al agua Aluminioestabilidad trmica complejosen ocasiones mejor desempeo Otros poliureaalta amplio rango de temperatura arcillasin punto de goteo, amplia temp. silicn sin punto de goteo, amplia temp. PTFEestabilidad trmica, alta temp.tipo subtipo caractersticas

-

Tipos de aditivosAntioxidantes mayor vida de la grasaAditivos Extrema Presin (EP) proteccin contra la soldadura en fro Aditivos contra la corrosin para proteger el rodamiento Aditivos slidos (grafito, MoS2) cuando el lubricante lquido falla

-

Consistencia de la grasa:Consistencia = 'grado de rigidez'Muy baja consistencia: escurrimiento de grasa, amazamiento excesivo

Muy alta consistencia:lubricacin pobre deslizamiento de rodillos

-

cono de pruebaMedicin de la consistencia: ( Nmero NLGI )

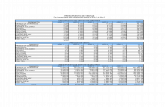

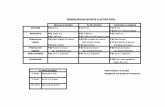

Indice Penetracin Apariencia Uso NLGI [* 0.1 mm]

000 445 475 Muy Lquida 00 400 430 Lquida reductores 0355 385 Semi-Lquida 1310 340 Muy Suave 2265 - 295 Suave rodamientos 3220 250 Medio Dura 4175 - 205 Dura 5130 - 160 Muy Durasellado 6 85 115 Extremadamente Dura

-

Seleccin rpida Se recomienda profundizar o pedir ayuda, si:la temperatura de operacin es mayor a 100 C o menor de 50 Cla velocidad es muy alta o muy bajael rodamiento soporta cargas muy pesadas o de impactose requieren propiedades especiales de la grasa: mayor resistencia al agua y a la corrosin, bajo par de rozamiento funcionamiento muy silencioso, compatibilidad con algn elemento del rodamiento.tc. Para la MAYORIA de las aplicaciones basta:Una grasa de alta calidad de jabn de Litio con aceite mineral y consistencia NLGI 2

-

Procedimiento de seleccin de grasa1Seleccione la consistencia

2Revise si son necesarios los aditivos EP o los lubricantes slidos

3Seleccione las propiedades adicionales de la grasa

4Seleccione la viscosidad del aceite baseProcedimiento simplificado

-

1. Seleccin de la consistenciaNLGI 2:en aplicaciones normales de rodamientos

NLGI 3: para rodamientos grandes, en situaciones de vibracin, a alta temperatura ambiente, en ejes con orientacin vertical

NLGI 1: a baja temperatura ambiente, aplicaciones oscilatorias, cuando la bombeabilidad de la grasa es indispensableUtilice:

-

2. Revise si se requieren aditivos EP/lub. slidosUse aditivos EP en caso de: - cargas elevadas (C/P < 5) - si hay cargas de impacto- si el equipo arranca y para con frecuenciaUtilice lubricantes slidos (grafito y MoS2) -solo si la velocidad de giro del rdto. es muy baja (n.dm < 30,000 mm/min) Use aditivos EP y lubricantes slidosSOLO cuando sean necesarios !!

-

3. Seleccione las propiedades adicionales de la grasaTemperatura de operacin espesante +menor a -30C o mayor a +120C) aceite baseResistencia al agua: espesante Proteccin conta la corrosin aditivos, espesante

Biodegradabilidad: aceite base

Si no se requieren propiedades adicionales : utilice una grasa con jabn de litio y aceite mineral En caso de: fjese en:

-

Seleccin de la viscosidad del aceite base:en caso de: selecciona:alta velocidad;carga ligera;baja temp.baja viscosidad baja velocidad;carga elevada alta viscosidadviscosidad: aplicacin:(a 40 C)(indicacin)

10-25 cStbaja temp., alta vel.70-200 cStaplicaciones comunes400-1000 cStcarga (muy) elevada, (muy) baja velocidad

-

4. Seleccione la viscosidad del aceite baseI.- Seleccione la viscosidad requerida n1 para lubricacin con aceite

II.- Convierta n1 a la viscosidad requerida n a 40C

III.- Selecione la viscosidad del aceite base de la grasa multipli- cando n por un factor de 2Diagramas

-

Valores de velocidad de las grasas SKFLGMT 2300,000LGMT 3300,000LGEP 2100,000LGWM 1100,000LGMB 210,000LGHB 2300,000LGEM 230,000LGEV 230,000LGLT 2700,000LGLC 2>700,000LGHQ 3500,000LGWA 2100,000LGFC 2300,000Valores mx. de n.dm [mm/min]n.dm: n = velocidad de giro (r.p.m.) dm = dimetro medio (mm)

-

Aplique el diagrama de relubricacin(Catlogo General de SKF)

Restricciones - condiciones normales de operacin - grasa de alta calidad base litio - temperaturas no excedan 70 C

Contacte a SKF en caso de: - aplicaciones crticas - grasas 'especiales' (sin jabn de Li) - condiciones anormales de operacin (vibracin, contaminacin, tc.)Intervalos de Relubricacin

-

Depende de:velocidad de giro del rodamiento (n)tamao de rodamiento. (d)tipo de rodamiento.NotasDiagrama vlido para 70 CPor cada 15 C arriba, (< 110C ), reduzca a la mitad el intervalo de relubricacin Por 15 C menos duplique la vida de la grasa solo una vezIntervalo de relubricacinAbf

-

Engrasado de por vida rodamiento sellado. seleccin inicial de la grasa muy importante. Relubricacin / reposicin ocasional rodamiento abierto. consulte el Catlogo General de SKF. Lubricacin continua para aplicaciones muy demandantes o con fines de proteccin contra la contaminacin, consulte al Catlogo General de SKF.Mtodos de lubricacin con grasa

-

Lubricacin inicialRodamientos abiertos:el rodamiento deber llenarse al 100% llene un 30-50% el espacio libre del alojamientoRodamientos con sellos o placas de proteccin:llenado normal = 25-35%solicite mayor llenado (grado 7 o 9) si se requiere proteccin contra la corrosin si se el rodamiento trabaja a baja velocidadsolicite menor llenado (grado 1) si el rodamiento opera a muy alta velocidad

-

Porqu falla la grasa ?Contaminacin con polvo, partculas abrasivas, tc. en almacenaje o en operacin Endurecimiento / degradacin el aceite se oxida o se pierde

Prdida de consistencia poca estabilidad mecnica contaminacin con agua o aceitel ! La vida de la grasa puede ser larga, pero no infinita!

-

Desempeo de la grasaEl desempeo de la grasa es un balance:

entre propiedades contrarias (en conflicto) - Lmites de operacin de alta y baja ..temperatura - Lmites de tempertura y vida de la grasa

entre propiedades de la grasa y su precio - los ingredientes para una grasa de alto ..desempeo son carosUna perfecta grasa Multiusos no existe !Para cada aplicacin se debe seleccionar la grasa ms adecuada

-

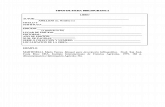

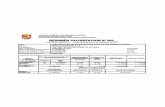

Ejemplo de una ficha tcnicaofrece: menor desgaste, funcionamiento silencioso, resistencia al agua, estabilidad a la oxidacin, proteccin contra la corrosinInformacin Tcnica especificacinNLGI 2tipo de aceite bade mineral tipo de jabn Litiocolor Caf oscuroViscosidad del aceite base mm /s a 40 C 190 mm /s a 100 C 16Penetracin 60 golpes, 10 mm 265-295 variacin depus de 100,000 golpes +50 mx.Punto de goteo, C 180SKF EMCOR, lavado con agua dest. 0-0SKF R2F, pruebas A y B 120 C pasaCarga de soldadura, N 280022-1SKF LGEP 2, grasa de extrema presin

-

Compatibilidad de la grasa (1)con los agentes de preservacin Las grasa convencionales de poliurea no son compatibles con la mayora de los agentes de preservacin! si hay problemas: limpie antes de engrasarcon otra grasaverifique la compatibilidad de los jabones y de los aceites base!existen tablas de compatibilidadla incompatibilidad no siempre genera problemas si hay problemas, limpie y reengrase

-

Compatibilidad de la grasa (2)con los materiales de la jaula:con los sellos de hule:Las grasas con aceites de ster no son compatibles en general con los sellos de polmero ACM!Los materiales de los sellos SKF son compatibles con la gran mayora de las grasasAzufre: los aditivos EP pueden atacar las jaulas de latn a temperaturas mayores de 100 C.Los aditivos EP pueden ser agresivos contra la jaula de poliamida (PA66) a temperaturas mayores a 60 C.

-

Especificacin de clavesTemperaturaM = media: -30 to +110 CH = alta:-20 to +130 CW = amplia:-40 to +140 CL = baja:-50 to + 80 CVelocidad rdtos de bolas rdtos de rodillosEH = extrem. alta:n.dm arriba 700,000 350,000VH = muy alta: n.dm hasta 700,000 350,000H = alta:n.dm hasta 500,000 250,000M = media:n.dm hasta 300,000 150,000L = baja:n.dm menor a 100,000 50,000Carga:H = alta:C/P < 5M = media:P = 5-10L = ligera: C/P > 10

*Building blocks of the course

Explain the logic behind the structure of this course. This will help the participants in structuring the information which they receive.For most participants the final aim of the course is to have a better insight in selecting the correct grease for an application. This selection process is discussed in block 3.But in order to make a good selection, you must have knowledge of the differences in performance of different greases. This is explained in block 2.And again in order to know which performance aspects are important for your application, you must have some basic understanding of grease lubrication. This is given in block 1.So block 1 gives information which is necessary for block 2, which in turn gives information which is needed for block 3.The video part is useful and nice as a break, but not essential.

*What should a grease do?

The participants should realise that a grease has more functions than to lubricate'.*The incredible performance of a lubricant:

Additional overhead sheet.

Make the participants realise how incredibly thin (0.1 - 1 micrometer) a lubricant film between rolling elements and bearing raceway is. This also stresses the importance of bearing quality (surface roughness) and the detrimental effect of even very small dirt particles.

The pressures in the lubricant film are also incredibly high (10,000-30,000 bar or atmosphere'). A lubricant is only able to keep the bearing surfaces separated because under the immense pressure the lubricant starts to behave as a solid, and becomes elastic rather than viscous (visco-elastic behaviour).

You may even tell the participants that under these extreme forces the rollers and raceways start to deform (they flatten a little). This is called elasto-hydrodynamic' lubrication, and create a larger surface area to support the bearing load.*Base oil viscosity (1)

The kinematic viscosity of base oils is usually expressed in centistokes (cSt), with the units mm2/s. Note that since base oil viscosity changes with temperature, it is always expressed at a given temperature. Often this temperature is 40 deg.C.*Importance of base oil viscosity

Base oil viscosity is the second important grease property which is discussed in detail.As expressed in block 1, base oil viscosity is chosen to achieve a compromise between acceptable film thickness and acceptable bearing friction.

Lubricant film thickness is dependent on the three factors listed in this overhead, which are usually not controllable. The only controllable parameter for influencing lubricant film thickness is base oil viscosity.*Grease or oil?

The big advantage of grease over oil is its consistency which makes it stay inside the bearing. Generally no feeding or retrieval systems are needed, which makes grease the cheapest lubrication solution.

Oil is generally used only when high speeds or operating temperatures preclude the use of grease, when frictional or applied heat has to be removed from the bearing position, or when adjacent components (gears etc.) are already lubricated with oil.*Base oil types

Traditionally from around 1900, mineral oils have been used. A mineral oil is basically part of a crude (earth) oil. Mineral oils are still appropriate for most applications.

But if enhanced properties are required, like reduced thickening at low temperatures or less thinning at high temperatures, chemically synthesised oils can have a better performance than mineral oils.

Natural oils are only used for bearings in food applications, or for greases classified as biodegradable. Note that there are also synthetic oils (esters) which are classified biodegradable.

The percentages in between brackets give an indication of the total usage (volume) of the oil types in greases for bearing lubrication.*Definition of a greaseA simplified way to explain what a grease is. If you look at a grease under the microscope, the thickener structure looks indeed like a sponge!

A simplified way to explain what a grease is. If you look at a grease under the microscope, the thickener structure looks indeed like a sponge!

The thickener sponge can release minute amounts of oil to lubricate the bearing contacts (oil bleeding'), and can even take the oil up again. This is the main advantage of a grease over an oil. An oil leaks away, a grease does not.*What's inside a grease?

Self-explaining.*Thickener types , additional

The reasons for using certain thickeners have been very much simpified. More knowledge is available within SKF.*Additive types

For simplicity restricted to 4 additive types.Anti-oxidants prevent/retard base oil oxidation, which leads to thickening of the base oil, making the oil ineffective.EP-additives react locally with the metal surfaces when the asperity tops touch, and form a thin protection film on the metal preventing cold welding of the metal parts.Solid additives are used as emergency lubrication' when a full lubricant film is not maintained anymore. Usually at very low bearing speed.*Consistency of the grease

Some people keep mixing up the concepts viscosity' and consistency'. Then it helps making a comparison with a sponge. A sponge may feel hard' or may feel soft', which is comparable with grease consistency. And with this sponge you may suck up water or shampoo, fluids which have different viscosities. (It is maybe a little over-simplified, but it explains the difference.)

*Measuring grease consistency

You may want to use again the comparison with butter.

Showing this apparatus may help in avoiding the confusion between NLGI number (increasing with harder greases) and the penetration number (decreasing with harder greases).*Grease selection without knowledge

Explain the effects which the current bearing developments will have on grease demands in the future. With this look into the future the presentation ends..

Note that it does NOT say that a Li-soap, mineral oil based grease is the prefered grease type. It only states that for most applications this type of grease will fulfil the lubrication demands.

In a 1-hour presentation, this is the only message regarding grease selection in general. How to select the best SKF aftermarket grease is shown in the chapter on SKF greases, somewhat further in this block.

In a 2-4 hour presentation, you can continue with a systematic approach of the grease selection process, using the following overheads.*Grease selection proces

A systematic approach is given for the selection of a grease. It is recognised that there are more ways to select a grease, but this shows a simple step-by-step method.

Note that this method leads to a grease profile: consistency, an indication of base oil or thickener type, special additives and base oil viscosity. It does not lead to a specific grease brand or type.

If extra help is needed to come from this grease profile to the selection of an SKF aftermarket grease, then additionally use the quick selection guide and the applciation profiles given later in this block.

*1 Select consistency

Note that in almost all occasions a consistency grade 2 will be the best choice.

The main danger of choosing a too high consistency is a reduction of oil bleeding, causing insufficient lubrication.

The main dangers of choosing a too low consistency are grease leakage and excessive grease churning leading to a further decrease of consistency. Also the temperature rise due to the increased friction will shorten the grease life.*2 Check EP / solid lubricant requirements

As explained in block 1, EP-additives are required when the contact surfaces are not fully separated by the lubricant film. This overhead list the the most frequently occuring causes.

Also explained in block 1, solid additives are needed when liquid lubrication fails. This is usually the case in (heavily loaded ) bearings running at very low speeds.

If not strictly necessary, EP-additives and solid lubricants should not be used. EP-additives can attack the bearing surface, and solid lubricants can interfere with normal liquid lubrication.*3 Select additional properties

Only a few additional properties are listed here. If more detailed questions arise you may want to use the two supplementary overheads on types of lubricating greases' in block 2.*Choice of base oil viscosity

You can make the effects of temperature, speed and load on film thickness intuitively understandable.

For example you may again want to use the comparison with aquaplaning of car tyres on a wet road to explain some of the relationships. For example when driving a light weight car at high speeds the chances of aquaplaning are higher than driving a heavy car slowly.

The temperature effects can be made clear by explaining that at lower temperatures the oils become thicker. Therefore at lower temperatures you need a thinner oil. Make your audience realise how much the base oil viscosity changes with temperature. For a mineral oil, the viscosity at 100 C is 5-10 times less than the viscosity at 40 C! This explains why bearing temperature is such a very important parameter in grease selection.

As a rule-of-thumb, some examples of viscosity ranges are given together with typical applications.

*4 Select base oil viscosity (1)

From the SKF General Catalogue (4000, page 160) diagram, select the required viscosity, based on bearing size (dm) and bearing speed.

Note that this gives the minimum required viscosity for oil lubrication at the application temperature of the bearing. Therefore this viscosity needs to be adjusted for temperature and to be adjusted for grease lubrication. This is shown in the next overhead.*Speed rating guidelines of SKF greases

The n.dm values on this overhead indicate a maximum bearing speed to which the grease should be subjected.

Different greases have different abilities to withstand shear. The shear rate to which a grease is subjected is directly related to the bearing speed rating. This bearing speed rating can be expressed in terms of n.dm value. This n.dm value is the bearing rotational speed n (revolutions/minute), multiplied by the mean bearing diameter dm (average of d and D, in mm).

Some participants may not understand why n.dm is used and not simply n. Explain that the rollers in a large bearing running at 1000 rev/min move much faster than in a small bearing running at 1000 rev/min. You may visualise this by comparing a large truck wheel (110 mm) with a normal car wheel (55 mm). If both wheels rotate with 1000 rev/min, then the car has a speed of 100 km/h, and the truck would have a speed of 200 km/h.

*Relubrication intervals

Explain the application constraints (most people tend to navigate blindly on this diagram, without thinking that the diagram is not always applicable).

Explain that lubrication intervals depend on so many things, that a lubrication interval is always an estimation, not a precise calculation.

Explain that the diagram gives estimations which are usually on the safe side. Because SKF has more knowledge on relubrication intervals than given in this diagram, the participant should not hesitate to contact SKF if he needs an update on the relubrication interval for his application.

*Relubrication intervals

Explain how to read the diagram (use an example).

Explain how to adjust the grease life for different temperatures.*Lubrication modes

Depending on how demanding an application is, bearings can be never, sometimes, or continuously relubricated.

Explain that also for sealed and greased-for-life bearings grease selection is important (for example depending on the operating temperature of the application). Selecting a sealed and greased-for-life bearing does not imply that it is suitable for all purposes!

Make the audience realise that continuous relubrication is often applied not for lubrication reasons, but just for sealing purposes. A good reason to consider applying sealed bearings.

Use this sheet as the introduction into relubrication interval estimation.

*Grease filling quantity

Self-explaining.

The former filling grades (A, Normal, U, B and C) have been replaced:grade A (10-15% fill) has been replaced by grade 1grade U (fill of unswept volume) has been replaced by grade 5grade B (45-60% fill) has been replaced by grade 7grade C (70-100% fill) has been replace by grade 9*Common causes of bearing failure

As mentioned before, 36% of all premature bearing failures are caused by inadequate lubrication. Contamination of the grease by dirt or (metal) particles causes roughening of the bearing contacts, which forms the onset of bearing seizure. Contamination can also lead to grease hardening.Grease life approaches its natural end when the grease has lost most of its oil, which causes grease hardening.If the grease is extensively overrolled in the roller-raceway contact, the thickener structure is disrupted and the grease softens. Grease softening leads to leakage and finally to insufficient lubrication.

*Grease performance

In a way a summary of this block. After this block the audience should be convinced that an all-purpose grease does not exist, and that it is really necessary that SKF has a range of greases available.

This overhead is also the introduction to the block 3: Selecting the proper grease.

*Technical specifications, example

Use this overhead to explain that strict technical specifications have been set for every SKF grease.

Most technical specifications have been discussed already in this course. A brief explanation on specifications not discussed in the course:

SKF Emcor, washout test: Instead of applying a mixture of grease and distilled water, the bearings are continuously flushed with distilled water.

SKF R2F test: Assesses the lubricating ability of the grease roller bearings in a housing. The A test is performed at room temperature. The B test, at 120 deg.C, assesses the high temperature performance of the grease.

4-Ball weld load test: Assesses the EP-performance of the grease, by measuring the load at which bearing balls in a 4-ball arrangement start to weld together.

*Grease compatibility (1)

Note that solutions are suggested in case compatibility problems arise.

If specific questions are asked on grease-grease compatibility, you can use the two compatibility tables which are given as supplementary overheads.*Grease compatibility (2)

The most frequently occuring compatibility issues are listed. *Specification of legends

Can be used as a further explanation of the legends in the previous overhead.