cigre400k

-

Upload

anuragjay12464 -

Category

Documents

-

view

228 -

download

0

Transcript of cigre400k

8/8/2019 cigre400k

http://slidepdf.com/reader/full/cigre400k 1/5

C:\Webpages\HVTech\CIGRE SC 21, St. Petersburg 1999 400 kV XLPE Bewag.doc

AFTER LAYING TESTS OF 400 kV XLPE CABLE SYSTEMS FOR BEWAG BERLIN

R. Plath; U. Herrmann K. Polster J. Spiegelberg; P. Coors

Institut „Prüffeld für elektrische Bewag-Berliner HIGHVOLT Prüftechnik Hochleistungstechnik“ Berlin Kraft-und Licht AG Dresden GmbH

Abstract. The after laying tests carried out on a 400 kV XLPE cable double-system (length 6.3 km)used AC test voltage combined with partial

discharges (PD) measurement on joints and sealingends for the first time. The approx. 30 MVA test power was delivered by the two-stage mobile

resonant test system of variable frequency whichwas specifically designed for this duty. The requirements to be met by the test system as well as

the test arrangement and its connection technology are explained. For the PD measurements, directional couplers were integrated into each joint.

The data measured on all joints were simultaneously recorded and centrally evaluated.The voltage tests carried out up to 400 kV and the

high-sensitive PD measurements done on the jointswith a PD detection level of 2 pC confirm that such test and measuring systems allow to achieveinformative commissioning and diagnostic tests on

extra high-voltage cables also under difficult on-site conditions

1. 400-kV cable installation

To enhance the long-term secure and economicalpower supply of Berlin, Bewag is building a 400 kVdiagonal interconnection through Berlin's load

centres.For the section between the substations of Mitte and

Friedrichshain, Bewag decided to use 400 kV XLPEinsulated cables for the first time /1/. They wereassembled in the continuous cable tunnel running at a

depth of approx. 25 m beneath the surface. The cablesuppliers were to successfully pass a one-year long-time test and a type test.

To assure the reliable and safe service life of thecable installation as a whole, quality assurancemeasures were an additional part of the project. They

included tests during the manufacturing process androutine tests conducted on every essential componentof the cable installation. Quality assurance was

completed by commissioning tests carried out afterassembling. It was checked whether there were anydefects produced during on-site assembling.

Therefore, the XLPE-insulated cable installation was

subjected to AC testing after assembling and at thesame time high-sensitive partial discharge (PD)

measurements were done on all accessoriessimultaneously.Due to the very high capacitive load, on-site AC

testing of the 6.3 km long cable link was only possibleby using the world-wide most powerful mobile

resonant test system. At the maximum test voltage level

of 400 kV RMS (√3 U0), the available test powerreached approx. 32 MVA at 25 Hz.

2.

Frequency-tuned resonant test systems

2.1 Principle of voltage generation

For commissioning HV testing of extruded HV cablesAC voltage of variable frequency (25 ... 300 Hz)became the preferred test voltage within few years

/2/,/3/, because of the realistic simulation of theoperational stress and the advantages of its generationby frequency-tuned test systems, which are among

others:

- the minimal specific weight (approx. 1kg/kVA) incomparison with resonant circuit with adjustable

inductance (approx. 5kg/kVA) as well as testtransformers with compensation (more than10kg/kVA),

- the lower feeding power (at least factor two incomparison with resonant circuits with adjustableinductance),

- the three-phase power supply, and

- the simple mechanic construction especially theresonant reactor has no movable parts.

The frequency-tuned resonant test system works as aseries resonant circuit. The resonant point is reached by

tuning the frequency converter to the natural frequency

of the series oscillation circuit (resonant reactor andcapacitive load). The frequency range of 30 ... 300 Hz

(1 :10) is generally accepted which means apermissible load range between minimum andmaximum test object capacitance of 1 : 100. The load

range can be increased up to 1 : 144 if the minimalfrequency of 25 Hz is permitted. In comparison withthem the resonant systems with adjustable inductance

have only an operating range of 1 : 20. Furthermore animportant characteristic is the frequency-dependentquality factor which can be described as the

comparison of the capacitive test power PP to the activepower PL. The power loss is mainly caused by the

losses of the reactor and the exciter transformer. Byusing a suitable construction of the resonant reactor a Qfactor greater than 100 can be achieved at least. In thiscase the feeding power is lower than one percent of the

test power.

8/8/2019 cigre400k

http://slidepdf.com/reader/full/cigre400k 2/5

2.2 Rating of the test systems

The technical data and the mechanic design of the

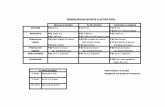

resonant reactor affect the parameters andcharacteristics of the test systems. The test conditionsof the 400 kV cable installation of BEWAG havebeen determined the nominal parameter of the testsystems which are as follows:

Vtest = 1.73 U0 = 400 kVC = 0.190 µF/km 6.3 km ≈ 2.2 µFf min = 25 HzI = 80 A, 8 h ON/16 h OFFP = 32 MVA (!)

Additionally the test system should also suitable fortesting of cables in a rated voltage range of 110 kV to220 kV as well as for 400 kV gas insulated

transmission lines (GIL) at 80% of the routine testlevel Vtest = 0.8*630 kV = 504 kV. Furthermore theweight of the transportation unit including trailer and

truck shall be taken into consideration because aweight of not more than 40 tons avoids a special

permission for the road traffic. These conditionsrequire to separate the resonant reactor into two units.Consequently, the frequency converter and theexciter transformer are separated too. As a result,

there are two independent test systems which canoperate separately or be connected in parallel (highertest power) or in series (higher test voltage) as well.

Hence, the second resonant reactor is installed on ainsulating construction which is rated for 254 kV (seealso Fig. 5). Thereby, the covered test cases are

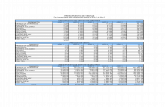

shown in Table 1 and Fig.1.

rated

volt.kV

test

voltagekV

capa-

citanceµF

cable

lengthkm

test

currentA

test

powerMVA

a)

110

132

150

220

160 (2.5Uo)

190

220

254 (2.0Uo)

2.5

2.5

2.1

1.6

12.5

12.5

10.5

8.0

64

75

80

80

10.3

14.3

17.6

20.3

b)

110

132

150

220

160 (2.5Uo)

190

220

254 (2.0Uo)

5.0

5.0

4.2

3.2

25

25

21

16

128

150

160

160

20.5

28.5

32.2

40.6

c) 400 400 (1.73Uo)

504 (0.8Up)

1.25

0.8

6.5

11.5*

78.5

80

31.4

40.3

* 70 nF/km

Table 1: Test system 2 x 80 A / 254 kVMaximum parameters of cable testinga) single test system

b) two test systems in parallelc) two test systems in series

The oil insulated resonant reactor is especiallydesigned for outdoor conditions with a steel tank and

an oil-to-air bushing of composite insulation (fibre-glass tube with silicon rubber sheds). Its nearly loadindependent inductance of 16 H is realised by an iron

core with multiple gaps which enable a linearmagnetization. The high quality factor is caused by aspecial design of this core and of the winding to

guarantee minimum losses. During the 1 hour testoperation the dissipation heat can usually drawed off by self-cooling from the surfaces of vessel and radia-

Fig. 1: Load-frequency and voltage characteristics

tors (ONAN). According to the BEWAG testconditions which request a test duration of 8 hours it isnecessary to cool the radiators with a ventilator(ONAF).

A minimum quality factor (design quality factor) of more than 100 at a frequency f = 25 Hz needs a feeding

power of only 200 kVA for a test power of 20 MVA.This is equal to the rated power of the frequencyconverter. Therefore the two frequency converterswork in a master-slave operation if the two resonant

reactors are connected in a series or parallel circuit.Additionally the two exciter transformers are circuitedon the primary side in parallel (Fig. 2) and on thesecondary side in series.

Fig. 2: Test circuit with 2 reactors in series

2.3 Acceptance test of the resonant test system

Before the resonant test system was used for the on-sitetests, it had been carefully tested at its rated voltage254 kV (1 hour including PD measurement) at voltagesup to 120% of this value, at test object punctures and so

on. These tests were repeated for the series and parallelconnection of two test systems.By means of switchable load capacitors and therefore

different resonant frequencies the semiautomaticoperation up to the test voltage was proven. Thevoltage measuring system was calibrated for the

operating frequency range from 25 Hz to 300 Hz. Theharmonic content of the test voltage meets therequirements of the international standard IEC 60060-1

and is always less than 5 percent. The measured qualityfactor confirms the calculated frequency response (Fig.3) and exceeds its design value (Q = 100) remarkably.

Therefore the requested test power of approximately

8/8/2019 cigre400k

http://slidepdf.com/reader/full/cigre400k 3/5

32 MVA can be generated by a feeding power of approx. 200 kVA.

Fig. 3: Quality factor Q and test power Pcharacteristics (design value Q = 100)

measured values

3. Tests

3.1 Test arrangement

The AC voltage test and the PD measurement on the400-kV cable installation was awarded to IPH, the

high-voltage and high-power test laboratory situatedat Berlin-Marzahn. The tests took place at thesubstation (GIS) of Friedrichsfelde.Due to its large dimensions the AC test system had tobe placed outside the cable installation and connectedby an additional test cable of 120 m length. One of its

ends was equipped with an SF6-sealing end forconnecting the test object. On the other side of thetest cable an SF6 sealing end was fitted in an SF6

tank, to which an outdoor sealing end was mounted.The voltage connection to the AC test system wasrealised by an aluminium tube (Fig. 4).

Fig. 4: Outdoor sealing end with test cable

One resonant reactor was used for the test up to 254

kV. It was mounted onto a trailer. Between resonantreactor and test cable terminal a blocking impedance

was arranged to reduce interferences for the PDmeasurement and to protect the resonant reactoragainst fast transients in case of breakdown. The

blocking impedance was mounted to a capacitivevoltage divider on one side and to a support on theother side. The voltage signal of the voltage divider is

used by the control and supply unit for voltageregulation and simultaneously for voltagemeasurement. The test voltage was furthermoremeasured by the integrated capacitive pick-up at theoutgoing bushing of the resonant reactor. The safety for

the tested cables was improved by providing a secondindependent switch-off device. To synchronise the PDmeasurement system to the test voltage phase, the AC

signal was transmitted via an optical link to the controlroom.The resonant reactor was supplied by an excitation

transformer placed next to the resonant reactor on thetrailer.The 400 kV tests need two AC test systems. A 254 kVtest system identical to that of IPH was thereforeprovided by KEMA. One of the two resonant reactorswas mounted to an insulating construction and both AC

test systems were series-connected (Fig. 2 and 5).

Fig. 5: Arrangement for 400-kV test

The voltage connection was arranged from the resonant

reactor on high-voltage potential to the test cable viathe blocking impedance which, in this case, wasmounted on a capacitive 500 kV voltage divider and a

500 kV support.

3.2 AC voltage tests

Since the tests anyway included the observation of the

PD level, the test voltage was increased by steps of 50kV/5 min until the final test voltage was reached.In the first part of the tests, the individual phases of each system were tested one after the other at the test

voltage of 254 kV requested by Bewag over a period of 15 min and after that at 230 kV over a 45-min period.With the cable capacitance being approx. 0.190 µF/km,

the resulting resonant frequency of the test circuit wasapprox. 37 Hz.The second part of the commissioning test was a loadtest for conditioning the cable installation with elevated

operating current (1685 - 1900 A). Over a 20-day pe-riod a cyclic load was applied to simulate potential ser-

vice conditions that may occur in future service life.Furthermore, the load test served to verify the effec-tiveness of the cable installation's forced air cooling.

In the last part of the tests, the test voltages of 1,73·U0

= 400 kV during 15 minutes and of 350 kV during 45

8/8/2019 cigre400k

http://slidepdf.com/reader/full/cigre400k 4/5

minutes were applied one after the other to each of the cable conductors. The result was a resonantfrequency of approx. 26 Hz for the test voltage. Fig. 6

shows the time characteristic of the 400-kV voltagetest, delivered by the computer control of the testsystem.

Fig. 6: Time characteristic

3.3 PD measurement

PD measurement was carried out only on the

accessories, because all cables were already testedduring the routine test.Each phase of both three-phase systems of the 6.3-km

cable installation included 8 joints and 2 GIS sealingends. On all of these accessories directional couplers /4/ for the decoupling of PD impulses were

additionally fitted.Bewag required simultaneous PD measurements onall these accessories to detect any PD as early aspossible. This was to minimise the risk of breakdown. During voltage testing no staff wasneeded inside the tunnel because the distributed

measurement system was under remote control byoptical links.Preliminary investigation showed that the noise level

in the tunnel was low as compared to typical on-siteconditions. The tunnel depth of 25 m and the largelength of cable between two joints attenuated high

frequency noise components very well. IPH designedand applied a PD measurement system fulfillingBewag requirements including a PD detection level

of ≤ 2 pC on site. Furthermore, two directionalcouplers left- and right-hand side of each joint

enabled on-site calibration and even high-precisionPD location.Capacitive sensors instead of directional couplers

were used for the GIS sealing ends of one of the twothree-phase cable systems. These sensors did notreach the same selectivity like the directional

couplers. Even at the far end, outer noise (e.g. PDfrom rain) superimposed the PD measurement at theGIS sealing end.

3.4 Test results

No breakdown occurred during all voltage tests. PD

measurements on 60 accessories (12 GIS sealing endsand 48 joints) showed PD in only one singlecase. Due to the low PD level (approx. 5 pC, singlepulses up to 7 pC) additional measurements were

carried out in order to be very sure before opening

the joint. After dismantling the joint, the PD causingfailure was found. The PD location executed before the

opening showed a displacement to the real failurelocation of approx. 2 cm, confirming the high accuracyof UHF measurement techniques. After repair, the jointreassembling was done exactly in the same place,because practically no damage on the cable insulationoccurred due to early fault recognition.

4. Conclusions

The experience from after laying tests of 400 kV XLEPcables with frequency-tuned resonant test systemsconfirms their simple erection on site, their easy

handling as well as their high reliability. Such testsystems for test voltages up to 500 kV and test powerup to 40 MVA are available.The test results confirm also the high overall qualitylevel of the 400-kV-XLPE cable system. Nevertheless,besides all routine tests on cables before laying and the

use of prefabricated and pretested accessories, a small

risk remains due to assembling work on accessories onsite. On-site AC testing combined with sensitive PD

measurements reduces this risk noticeably.

5. References

/1/ Henningsen, C. H., Polster, K., Müller, K. B.,Schroth, R. G.:

New 400 kV XLEP long distance cable systems,their first application for the power supply of Berlin,

CIGRE Session (1998), paper 21-109

/2/ Schufft, W. et al.:Powerful frequency-tuned resonant test systemsfor after-laying tests of 110 kV XLPE cables.9th ISH Graz 1995, paper 49.86

/3/ Hauschild, W., Schufft, W., Spiegelberg J.:Alternating voltage on-site testing of XLPE

cables: The parameter selection of frequency-tuned resonant test systems.10th ISH Montreal (1997),Vol. 4, pp. 75-78

/4/ Pommerenke, D., Strehl, T., Kalkner, W.:Directional coupler sensor for partial discharge

recognition in high voltage cable systems.10. ISH Montreal 1997

Address of author:

Dr. Ing. R. Plath

Institut Prüffeld f. Hochleistungstechnik Berlin (IPH)Landsberger Allee 376

12632 Berlin

8/8/2019 cigre400k

http://slidepdf.com/reader/full/cigre400k 5/5

C:\Webpages\HVTech\CIGRE SC 21, St. Petersburg 1999 400 kV XLPE Bewag.doc