Artículo Científico DOI: Indexada Latindex ISSN 2602-8093 ...

Indice · TD30A ±0 TD303 2 TD302 12 TD30D 14 TORRE TD3 MATRIZ DE CORRIDAS PARA DISEÑO ESTRUCTURAL...

Transcript of Indice · TD30A ±0 TD303 2 TD302 12 TD30D 14 TORRE TD3 MATRIZ DE CORRIDAS PARA DISEÑO ESTRUCTURAL...

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 1

Indice

1. GENERALIDADES 2 2. NORMAS 4 2.1. MATERIALES 4 2.2. ESPESOR MINIMO PERMITIDO 4 2.3. ESBELTEZ MAXIMA DE LOS MIEMBROS 4 2.4. INGENIERIA DE DETALLE 4 3. DIAGRAMAS DE CARGAS 5 4. VIENTO SOBRE LA ESTRUCTURA 14 5. OUTPUT 18 6. VERIFICACION DE MIEMBROS 38 7. REACCIONES 41 8. DESPLAZAMIENTOS 42 9. DISEÑO DE HIERRO DE ANCLAJE (STUB) 43 10. CALCULO DE TRAVESAÑOS DEL STUB (CLEATS) 44

Ver Plano de Cuerpo Basico No. SIEPAC-L1-GE-S-PL-2600 REV A 2-2

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 2

1.- GENERALIDADES.

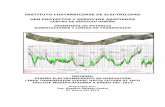

La presente memoria de calculo tiene por objeto desarrollar el diseño de la torre de suspension autosoportada tipo TD3. En el diseño se han considerado los diagramas de cargas de la Memoria de Calculo C2-I-CON-0001-70620 Rev. D y las recomendaciones de la SECCION VI ESPECIFICACIONES TECNICAS, CAPITULO No. V ESPECIFICACIONES PARA EL DISEÑO FINAL de la EPR. La solución de la estructura se realiza mediante la utilización del programa (TOWER) Este programa permite la resolución de sistemas hiperestaticos especiales de múltiples incógnitas mediante el planteo matricial del método de las rigideces. Para el diseño estructural de los elementos de la torre, se emplearon las envolventes de fuerzas actuantes que resultaron del análisis de los niveles (cuerpos o aumentos) de la torre con los siguientes arreglos de extensiones. Modelo 1 a 2.- Las cuatro extensiones +3 en cada nivel. Modelo 3 a 4.- Las cuatro extensiones +2 en cada nivel. Modelo 5 a 6.- Las cuatro extensiones -4 en cada nivel.

Modelo 7 a 14.- Tres extensiones más largas combinadas con una extensión mas corta.

El análisis de estos modelos 7 al 14 se realizan ubicando sucesivamente la extensión mas corta en cada apoyo de la torre. VER MATRIZ DE CORRIDAS PARA DISEÑO ESTRUCTURAL.

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 3

EXT.+3 EXT.+3 EXT.+3 EXT.+3

VIENTO VIENTOTRANSVERSAL TRANSVERSAL

EXT.+3 EXT.-4 EXT.-4 EXT.+3

EXT.-4 EXT.+3 EXT.+3 EXT.-4

VIENTO VIENTOTRANSVERSAL TRANSVERSAL

EXT.+3 EXT.+3 EXT.+3 EXT.+3

7 ARREGLO D

ARREGLO A

ARREGLO A4

5 ARREGLO B

TD33D13

11

3

6 ARREGLO C

4 EXT. -4

TD33B9

TD33C

1 4 EXT. +3

2

TD33-45

TD33A7

ARREGLO D

EXTENSIONES

4 EXT. +2

ARREGLO C

+3TD333

1

TD3323

ARREGLO B

TD30-46

TD30A

±0TD303

2

TD302

12

TD30D14

TORRE TD3 MATRIZ DE CORRIDAS PARA DISEÑO ESTRUCTURAL

N I V E L E S

8

TD30B10

TD30C

4

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 4

2.- NORMAS. Las siguientes normas han sido consideradas:

� ASCE Guide for design of steel transmission towers nº 52 - Second Edition � ANSI/ASCE 10-90 Design of lattice steel transmission structures (Dec. 1991) � ASTM � Especificaciones Tecnicas de la EPR

2.1.- Materiales

� Perfiles angulos laminados en caliente, calidad:

ASTM A36. ASTM A572 gr. 50

� Placas calidad ASTM A36. � Tornillos ASTM A394 Tipo 0

Cortante : 3226 Kg/cm2

Aplastamiento A36 : 6117 Kg/cm2

Aplastamiento A572 gr. 50 : 6855 Kg/cm2

Mínima dimensiones de tornillos : ∅= 1/2" 2.2. Espesor mínimo permitido

Para miembros principales : 6.0 mm. Para los otros miembros : 4.0 mm. Placas en estructura : 5.0 mm.

2.3.- Esbeltez máxima de los miembros Para miembros principales : 150 Para los otros miembros comprimidos : 200 Para los otros miembros redundantes : 250 Para los otros miembros tendido : 500

2.4.- Ingeniería de detalle � Los elementos estructurales cuyo eje longitudinal con la horizontal formen un ángulo

de 45º, deben resistir una carga concentrada de 100 Kg. perpendicular al eje longitudinal (incluido en análisis estructural), aplicada en cualquier punto de su longitud. De acuerdo a lo descrito en el ASCE 10-97 en 3.14.8.

� El elemento redundante debe tener capacidad para soportar, por lo menos el 2.5% de la fuerza actuante en elemento principal que arriostra.

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 5

3.- DIAGRAMAS DE CARGAS. TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

327 100 327 221 280 120 280 120

300 100 29 23

1 2 1 2

1112100 1112

100 969

229 969

229

708 708 84 84

3 4 3 4

1112100 1112

100 969

229 969

229

708 708 84 84

5 6 5 6

1112100 1112

100 969

229 969

229

708 708 84 84

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

230 Kg/m² 230 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.5 FS= 1.5

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

327 120 327 120 280 735 280 0

162 120 13 21

1 2 1 2

HIP: I VIENTO MAXIMO TRANSVERSAL 90° HIP: II VIENTO MAXIMO LONGITUDINAL

1112220 1112

220 969

0

397 397 72

3 4 3 4

1112220 1112

220 969

0

397 397 72

5 6 5 6

1112220 1112

220 969

0

397 397 72

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

163 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.5 FS= 1.2

HIP: IV CONTENCION DE FALLA HG 1 (1 Cto.)HIP: III VIENTO MAXIMO A 45°

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 6

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

280 0 280 594 280 0 280 0

26 10 26 21

1 2 1 2

9690

969

2077

72 36

3 4 3 4

0

969 969 0

72 72

5 6 5 6

969 0 969 0

72 72

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.2 FS= 1.2

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

280 0 280 0 280 0 280 0

26 21 26 21

1 2 1 2

HIP: IV CONTENCION DE FALLA HG 2 (1 Cto.) HIP: IV CONTENCION DE FALLA COND 3 (1 Cto.)

969 0 969 0

72 72

3 4 3 4

969

2077

9690

36 72

5 6 5 6

9690

969

2077

72 72

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.2 FS= 1.2

HIP: IV CONTENCION DE FALLA COND 5 (1 Cto.) HIP: IV CONTENCION DE FALLA COND 7 (1 Cto.)

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 7

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

280 735 280 594 280 735 280 0

13 10 13 21

1 2 1 2

9690

9690

9690

969

2077

72 72 72 36

3 4 3 4

969 0 969 0 969 0 969 0

72 72 72 72

5 6 5 6

969 0 969 0 969 0 969 0

72 72 72 72

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.2 FS= 1.2

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

280 735 280 0 280 735 280 0

13 21 13 21

1 2 1 2

HIP: IV CONTENCION DE FALLA HG 1 + HG 2 (2 Ctos.) HIP: IV CONTENCION DE FALLA HG 1 + COND 4 (2 Ctos.)

969 0 969 0 969 0 969 0

72 72 72 72

3 4 3 4

9690

969

2077

9690

9690

72 36 72 72

5 6 5 6

9690

9690

9690

969

2077

72 72 72 36

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.2 FS= 1.2

HIP: IV CONTENCION DE FALLA HG 1 + COND 6 (2 Ctos.) HIP: IV CONTENCION DE FALLA HG 1 + COND 8 (2 Ctos.)

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 8

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

280 0 280 0 280 0 280 0

26 21 26 21

1 2 1 2

969

2077

969

2077

969

2077

9690

36 36 36 72

3 4 3 4

9690

9690

9690

969

2077

72 72 72 36

5 6 5 6

969 0 969 0 969 0 969 0

72 72 72 72

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.2 FS= 1.2

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

280 0 280 0 280 0 280 0

26 21 26 21

1 2 1 2

HIP: IV CONTENCION DE FALLA COND 3 + COND 4 (2 Ctos.) HIP: IV CONTENCION DE FALLA COND 3 + COND 6 (2 Ctos.)

969

2077

9690

9690

9690

36 72 72 72

3 4 3 4

9690

9690

969

2077

969

2077

72 72 36 36

5 6 5 6

9690

969

2077

9690

9690

72 36 72 72

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.2 FS= 1.2

HIP: IV CONTENCION DE FALLA COND 3 + COND 8 (2 Ctos.) HIP: IV CONTENCION DE FALLA COND 5 + COND 6 (2 Ctos.)

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 9

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

280 0 280 0 280 0 280 0

26 21 26 21

1 2 1 2

969 0 969 0 969 0 969 0

72 72 72 72

3 4 3 4

969

2077

9690

9690

9690

36 72 72 72

5 6 5 6

9690

969

2077

969

2077

969

2077

72 36 36 36

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.2 FS= 1.2

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

280 735 280 0 280 0 280 0

13 21 26 21

1 2 1 2

HIP: IV CONTENCION DE FALLA COND 5 + COND 8 (2 Ctos.) HIP: IV CONTENCION DE FALLA COND 7 + COND 8 (2 Ctos.)

9690

9690

969

2077

9690

72 72 36 72

3 4 3 4

969 0 969 0 969 0 969 0

72 72 72 72

5 6 5 6

969 0 969 0 969 0 969 0

72 72 72 72

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.2 FS= 1.2

HIP: IV CONTENCION DE FALLA HG 1 (2 Ctos.) HIP: IV CONTENCION DE FALLA COND 3 (2 Ctos.)

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 10

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

280 0 280 0 280 0 280 0

26 21 26 21

1 2 1 2

969 0 969 0 969 0 969 0

72 72 72 72

3 4 3 4

969

2077

9690

9690

9690

36 72 72 72

5 6 5 6

9690

9690

969

2077

9690

72 72 36 72

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.2 FS= 1.2

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

280 188 280 118 787 514

3 2 9

1 2 1 2

HIP: IV CONTENCION DE FALLA COND 5 (2 Ctos.) HIP: IV CONTENCION DE FALLA COND 7 (2 Ctos.)

969418 969

418 969

0

7 7 72

3 4 3 4

969418 969

418 969

0

7 7 72

5 6 5 6

969418 969

418 969

0

7 7 72

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.2 FS= 1.7

HIP: V DESBALANCE LONGITUDINAL HIP: VI TENDIDO DE CABLES HG 1 (1 Cto)

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 11

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

280 0 280 0

26 26

1 2 1 2

1946

1454

9690

25 72

3 4 3 4

969 0 969 0

72 72

5 6 5 6

9690

1946

1454

72 25

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.7 FS= 1.7

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

787 514 280 0 280 0 280 0

9 21 26 21

1 2 1 2

HIP: VI TENDIDO DE CABLES COND 3 (1 Cto) HIP: VI TENDIDO DE CABLES COND 7 (1 Cto)

9690

9690

1946

1454

9690

72 72 25 72

3 4 3 4

969 0 969 0 969 0 969 0

72 72 72 72

5 6 5 6

969 0 969 0 969 0 969 0

72 72 72 72

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.7 FS= 1.7

HIP: VI TENDIDO DE CABLES HG 1 (2 Ctos) HIP: VI TENDIDO DE CABLES COND 3 (2 Ctos)

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 12

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

280 0 280 0 810 0

26 21 26

1 2 1 2

969 0 969 0 969 0

72 72 72

3 4 3 4

969 0 969 0 969 0

72 72 72

5 6 5 6

1946

1454

9690

9690

25 72 72

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.7 FS= 1.7

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

280 0 280 0

26 26

1 2 1 2

HIP: VI TENDIDO DE CABLES COND 7 (2 Ctos) HIP: VII MANTENIMIENTO HG 1 (1 Cto.)

2188 0 969 0

72 72

3 4 3 4

969 0 969 0

72 72

5 6 5 6

969 0 2188 0

72 72

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.7 FS= 1.7

HIP: VII MANTENIMIENTO COND 3 (1 Cto.) HIP: VII MANTENIMIENTO COND 7 (1 Cto.)

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 13

TORRE TIPO " TD3 " TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m USO : 2° / 400 / 600 m

810 0 280 0 280 0 280 0

26 21 26 21

1 2 1 2

969 0 969 0 2188 0 969 0

72 72 72 72

3 4 3 4

969 0 969 0 969 0 969 0

72 72 72 72

5 6 5 6

969 0 969 0 969 0 969 0

72 72 72 72

7 8 7 8

Las cargas no estan afectadas por Las cargas no estan afectadas por

su factor correspondiente su factor correspondiente

PRESION DE VIENTO EN TORRE PRESION DE VIENTO EN TORRE

0 Kg/m² 0 Kg/m²

CARGAS EN Kg CARGAS EN Kg

FS= 1.7 FS= 1.7

TORRE TIPO " TD3 "

USO : 2° / 400 / 600 m

280 0 280 0

26 21

1 2

HIP: VII MANTENIMIENTO HG 1 (2 Ctos.) HIP: VII MANTENIMIENTO COND 3 (2 Ctos.)

969 0 969 0

72 72

3 4

969 0 969 0

72 72

5 6

2188 0 969 0

72 72

7 8

Las cargas no estan afectadas por

su factor correspondiente

PRESION DE VIENTO EN TORRE

0 Kg/m²

CARGAS EN Kg

FS= 1.7

HIP: VII MANTENIMIENTO COND 7 (2 Ctos.)

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 14

4.- VIENTO SOBRE LA ESTRUCTURA

Viento longitudinal

Velocidad de referencia Vo=100 Km/H Presion = (Vo/3.6)²/16 = 48 kg/m²ct = fijo k = 1 (invariable con la altura)

Rugosidad: B Barras planas Fuerza: At = (Vo/3.6)²/16*St*Ct*K²

(m) (m) n (m²)

MONT 0.045 1.2 2 0.108CORD SUP 0.04 5.6 2 0.448CORD INF 0.055 5 2 0.550

MONT 0.06 1.4 2 0.168CORD SUP 0.06 4.1186 2 0.494CORD INF 0.06 3.8733 2 0.465

DIAG 0.045 2.1 2 0.189TRAV. SUP 0.05 1.5 1 0.075TRAV. INF 0.06 1.5 1 0.090

ARRIOST 0.04 6.9 2 0.552ARRIOST cond 0.04 4.4 2 0.352

∑ = 3.49 13.72 0.25 3.2 1 539 124

MONT 0.6 5.9 2 0.708CORD SUP 0.6 4.1186 2 0.494CORD INF 0.6 3.8733 2 0.465

DIAG 0.045 6.3639 2 0.573DIAG 0.04 2.0518 2 0.164

TRAV. SUP 0.05 1.5 1 0.075TRAV. INF 0.06 1.5 1 0.090ARRIOST 0.04 4.4 2 0.352

∑ = 2.92 14.17 0.21 3.2 1 451 120

MONT 0.08 5.9 2 0.944CORD SUP 0.06 4.3038 2 0.516CORD INF 0.06 4.0697 2 0.488

DIAG 0.045 6.3639 2 0.573DIAG 0.045 2.0518 2 0.185

TRAV. SUP 0.05 1.5 1 0.075TRAV. INF 0.06 1.5 1 0.090ARRIOST 0.04 4.4 2 0.352ARRIOST 0.04 0.8 2 0.064

∑ = 3.29 14.45 0.23 3.2 1 507 109

MONT 0.1 5.6178 2 1.124DIAG 0.045 5.463 2 0.492DIAG 0.04 2.6904 2 0.215

ARRIOST 0.04 6.6 2 0.528

∑ = 2.36 11.24 0.21 3.2 1 364 129

MONT 0.1 5.74 2 1.148DIAG 0.045 3.81 2 0.3429DIAG 0.05 4.54 2 0.454

ARRIOST 0.04 6.61 2 0.5288

∑ = 2.47 17.51 0.14 3.2 1 381 95

S bruta (m²)

Area neta St X (m²/m²)

TRONCO SUP 1/2

MENSULA

sector de

torreGrupo

HG MENSULA

TRONCO SUP 2/2

MENSULA

TRONCO 1/2 INF

k²At

(kg)

Carga en c/u de

4 nudos

z (m)

Ct

TRONCO 2/2 INF

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 15

Viento longitudinal

Velocidad de referencia Vo=100 Km/H Presion = (Vo/3.6)²/16 = 48 kg/m²ct = fijo k = 1 (invariable con la altura)

Rugosidad: B Barras planas Fuerza: At = (Vo/3.6)²/16*St*Ct*K²

(m) (m) n (m²)

MONT 0.1 0.83 2 0.166DIAG 0.051 1.72 2 0.175TRAV. 0.044 3.17 1 0.139

∑ = 0.481 2.547 0.19 3.2 1 74 16

MONT 0.1 3.12 2 0.624MONT 0.1 0.72 2 0.144DIAG 0.05 4.54 2 0.454DIAG 0.044 1.68 2 0.148DIAG 0.04 0.77 2 0.062TRAV. 0.05 3.6 1 0.180TRAV. 0.04 1.59 2 0.127

∑ = 1.74 12.9 0.13 3.2 1 269 67

MONT 0.1 1 2 0.200DIAG 0.06 1.95 2 0.234

∑ = 0.434 0.793 0.55 3.2 1 67 18

MONT 0.1 7.03 2 1.406DIAG 0.06 7.44 2 0.893

ARRIOST 0.035 12.31 2 0.862ARRIOST 0.035 0.86 2 0.060

∑ = 3.22 6.85 0.47 3.2 1 497 124

MONT 0.1 8.03 2 1.606DIAG 0.06 8.35 2 1.002

ARRIOST 0.035 12.31 2 0.862ARRIOST 0.035 2.03 2 0.142

∑ = 3.61 7.16 0.5 3.2 1 557 139

EXT -4

NIVEL +0

EXT +2

EXT +3

sector de

torreGrupo

Area neta StS

bruta (m²)

X (m²/m²)

Ctz

(m)k²

At (kg)

Carga en c/u de

4 nudos

NIVEL +3

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 16

Viento transversal

Velocidad de referencia Vo=100 Km/H Presion = (Vo/3.6)²/16 = 48 kg/m²ct = fijo k = 1 (invariable con la altura)

Rugosidad: B Barras planas Fuerza: At = (Vo/3.6)²/16*St*Ct*K²

(m) (m) n (m²)

TRAV 0.04 1.5 1 0.060MONT 0.045 1.2 2 0.108MONT 0.06 1.4 2 0.168

CORD INF 0.06 1.6 2 0.192TRAV. SUP 0.04 1.5 1 0.060

DIAG 0.04 2.052 2 0.164TRAV SUP 0.04 1.5 1 0.060TRAV. INF 0.04 1.5 1 0.060CORD SUP 0.06 1.3 2 0.156ARRIOST 0.04 6 1 0.240

∑ = 1.27 3.15 0.4 3.2 1 196 58

MONT 0.06 5.9 2 0.708DIAG 0.045 6.364 2 0.573DIAG 0.04 2.052 2 0.164

TRAV SUP 0.04 1.5 1 0.060TRAV INF 0.04 1.5 1 0.060

CORD SUP 0.06 1.3 2 0.156

∑ = 1.72 8.85 0.19 3.2 1 266 71

MONT 0.08 5.9 2 0.944DIAG 0.045 6.364 2 0.573DIAG 0.04 2.052 2 0.164

TRAV SUP 0.04 1.5 1 0.060TRAV INF 0.05 1.5 1 0.075

CORD SUP 0.06 1.3 2 0.156

∑ = 1.97 8.85 0.22 3.2 1 304 84

MONT 0.1 5.618 2 1.124DIAG 0.045 5.463 2 0.492DIAG 0.04 2.69 2 0.215

ARRIOST 0.04 6.6 2 0.528

∑ = 2.36 11.24 0.21 3.2 1 364 129

MONT 0.1 5.74 2 1.148DIAG 0.045 3.81 2 0.3429DIAG 0.05 4.54 2 0.454

ARRIOST 0.04 6.61 2 0.5288

∑ = 2.47 17.51 0.14 3.2 1 381 95

sector de

torre

TRONCO 1/2 INF

TRONCO SUP 2/2

MENSULA

GrupoArea neta St

S bruta (m²)

X (m²/m²)

Ctz

(m)k²

At (kg)

Carga en c/u de

4 nudos

HG MENSULA

TRONCO SUP 1/2

MENSULA

TRONCO 2/2 INF

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 17

Viento transversal

Velocidad de referencia Vo=100 Km/H Presion = (Vo/3.6)²/16 = 48 kg/m²ct = fijo k = 1 (invariable con la altura)

Rugosidad: B Barras planas Fuerza: At = (Vo/3.6)²/16*St*Ct*K²

(m) (m) n (m²)

MONT 0.1 0.83 2 0.166DIAG 0.051 1.72 2 0.175TRAV. 0.044 3.17 1 0.139

∑ = 0.481 2.547 0.19 3.2 1 74 16

MONT 0.1 3.12 2 0.624MONT 0.1 0.72 2 0.144DIAG 0.05 4.54 2 0.454DIAG 0.044 1.68 2 0.148DIAG 0.04 0.77 2 0.062TRAV. 0.05 3.6 1 0.180TRAV. 0.04 1.59 2 0.127

∑ = 1.74 12.9 0.13 3.2 1 269 67

MONT 0.1 1 2 0.200DIAG 0.06 1.95 2 0.234

∑ = 0.434 0.793 0.55 3.2 1 67 18

MONT 0.1 7.03 2 1.406DIAG 0.06 7.44 2 0.893

ARRIOST 0.035 12.31 2 0.862ARRIOST 0.035 0.86 2 0.060

∑ = 3.22 6.85 0.47 3.2 1 497 124

MONT 0.1 8.03 2 1.606DIAG 0.06 8.35 2 1.002

ARRIOST 0.035 12.31 2 0.862ARRIOST 0.035 2.03 2 0.142

∑ = 3.61 7.16 0.5 3.2 1 557 139

EXT +2

EXT +3

At (kg)

Carga en c/u de

4 nudos

Area neta StS

bruta (m²)

X (m²/m²)

Ctz

(m)k²

sector de

torreGrupo

NIVEL +0

NIVEL +3

EXT -4

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 18

5.- OUTPUT

******************************************************************************* * * * TOWER - Analysis and Design - Copyright Power Line Systems, Inc. 1986-2006 * * * ******************************************************************************* Project Name : Project Notes: Project File : d:\My Documents\TD3\TD333.tow Date run : 11:10:59 AM Friday, January 18, 2008 by : Tower Version 8.10 Licensed to : Techint Member check option: ASCE 10 Connection rupture check: ASCE 10 Crossing diagonal check: Fixed Joints Geometry: Joint Symmetry X Coord. Y Coord. Z Coord. X Disp. Y Disp. Z Disp. X Rot. Y Rot. Z Rot. Label Code (m) (m) (m) Rest. Rest. Rest. Rest. Rest. Rest. ---------------------------------------------------------------------------------------------- 1P Y-Symmetry 0.75 0 14.2 Free Free Free Free Free Free 2P XY-Symmetry 0.75 0.75 13.2 Free Free Free Free Free Free 3P XY-Symmetry 0.75 0.75 0 Free Free Free Free Free Free 4P XY-Symmetry 1.798 1.798 -11.28 Free Free Free Free Free Free 5P X-Symmetry 0 5.55 14.85 Free Free Free Free Free Free 6P X-Symmetry 0 4.55 11.8 Free Free Free Free Free Free 7P X-Symmetry 0 4.55 5.9 Free Free Free Free Free Free 8P X-Symmetry 0 4.75 0 Free Free Free Free Free Free 9P None 2.422 1.572 -18 Free Free Free Free Free Free 10P None 1.572 2.422 -18 Free Free Free Free Free Free 9AP None -1.542 2.422 -18 Free Free Free Free Free Free 10AP None -2.422 1.572 -18 Free Free Free Free Free Free 9BP None -2.422 -1.542 -18 Free Free Free Free Free Free 10BP None -1.542 -2.422 -18 Free Free Free Free Free Free 9CP None 1.542 -2.422 -18 Free Free Free Free Free Free 10CP None 2.422 -1.542 -18 Free Free Free Free Free Free 1Y Y-Gen -0.75 0 14.2 Free Free Free Free Free Free 2X X-GenXY 0.75 -0.75 13.2 Free Free Free Free Free Free 2XY XY-GenXY -0.75 -0.75 13.2 Free Free Free Free Free Free 2Y Y-GenXY -0.75 0.75 13.2 Free Free Free Free Free Free 3X X-GenXY 0.75 -0.75 0 Free Free Free Free Free Free 3XY XY-GenXY -0.75 -0.75 0 Free Free Free Free Free Free 3Y Y-GenXY -0.75 0.75 0 Free Free Free Free Free Free 4X X-GenXY 1.798 -1.798 -11.28 Free Free Free Free Free Free 4XY XY-GenXY -1.798 -1.798 -11.28 Free Free Free Free Free Free 4Y Y-GenXY -1.798 1.798 -11.28 Free Free Free Free Free Free 5X X-Gen 0 -5.55 14.85 Free Free Free Free Free Free 6X X-Gen 0 -4.55 11.8 Free Free Free Free Free Free 7X X-Gen 0 -4.55 5.9 Free Free Free Free Free Free 8X X-Gen 0 -4.75 0 Free Free Free Free Free Free Secondary Joints: Joint Symmetry Origin End Fraction Elevation X Disp. Y Disp. Z Disp. X Rot. Y Rot. Z Rot. Label Code Joint Joint Rest. Rest. Rest. Rest. Rest. Rest. (m) -------------------------------------------------------------------------------------------------------- 21S XY-Symmetry 2P 3P 0 11.8 Free Free Free Free Free Free 21AS Y-Symmetry 21S 21X 0.5 0 Free Free Free Free Free Free 22S XY-Symmetry 2P 3P 0 10.3 Free Free Free Free Free Free 23S XY-Symmetry 2P 3P 0 8.8 Free Free Free Free Free Free 24S XY-Symmetry 2P 3P 0 7.3 Free Free Free Free Free Free 25S XY-Symmetry 2P 3P 0 5.9 Free Free Free Free Free Free 25AS Y-Symmetry 25S 25X 0.5 0 Free Free Free Free Free Free 3AS Y-Symmetry 3P 3X 0.5 0 Free Free Free Free Free Free 26S XY-Symmetry 2P 3P 0 4.4 Free Free Free Free Free Free 27S XY-Symmetry 2P 3P 0 2.9 Free Free Free Free Free Free 28S XY-Symmetry 2P 3P 0 1.4 Free Free Free Free Free Free 29S XY-Symmetry 3P 4P 0 -1.543 Free Free Free Free Free Free 30S XY-Symmetry 3P 4P 0 -3.381 Free Free Free Free Free Free 31S XY-Symmetry 3P 4P 0 -5.57 Free Free Free Free Free Free 32S XY-Symmetry 3P 4P 0 -8.177 Free Free Free Free Free Free 34S XY-Symmetry 2P 3P 0 12.5 Free Free Free Free Free Free 35S XY-Symmetry 2P 3P 0 11.05 Free Free Free Free Free Free 36S XY-Symmetry 2P 3P 0 9.55 Free Free Free Free Free Free 37S XY-Symmetry 2P 3P 0 8.05 Free Free Free Free Free Free 38S XY-Symmetry 2P 3P 0 6.6 Free Free Free Free Free Free 39S XY-Symmetry 2P 3P 0 5.15 Free Free Free Free Free Free 40S XY-Symmetry 2P 3P 0 3.65 Free Free Free Free Free Free 41S XY-Symmetry 2P 3P 0 2.15 Free Free Free Free Free Free 42S XY-Symmetry 2P 3P 0 0.7 Free Free Free Free Free Free

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 19

43S X-Symmetry 2P 2Y 0.5 0 Free Free Free Free Free Free 44S X-Symmetry 21S 21Y 0.5 0 Free Free Free Free Free Free 45S X-Symmetry 24S 24Y 0.5 0 Free Free Free Free Free Free 46S X-Symmetry 25S 25Y 0.5 0 Free Free Free Free Free Free 47S X-Symmetry 28S 28Y 0.5 0 Free Free Free Free Free Free 48S X-Symmetry 3P 3Y 0.5 0 Free Free Free Free Free Free 53S Y-Symmetry 4P 4X 0.5 0 Free Free Free Free Free Free 54S X-Symmetry 4P 4Y 0.5 0 Free Free Free Free Free Free 55S XY-Symmetry 4P 53S 0.4 0 Free Free Free Free Free Free 56S XY-Symmetry 4P 54S 0.4 0 Free Free Free Free Free Free 57S XY-Symmetry 55S 54S 0.29 0 Free Free Free Free Free Free 58S XY-Symmetry 55S 54S 0.6 0 Free Free Free Free Free Free 59S XY-Symmetry 53S 56S 0.4 0 Free Free Free Free Free Free 60S XY-Symmetry 3P 4P 0 -12 Free Free Free Free Free Free 61S XY-Symmetry 60S 60X 0.4253 0 Free Free Free Free Free Free 62S XY-Symmetry 60S 60Y 0.4253 0 Free Free Free Free Free Free 63S None 3P 4P 0 -20 Fixed Fixed Fixed Fixed Fixed Fixed 64S None 3Y 4Y 0 -20 Fixed Fixed Fixed Fixed Fixed Fixed 65S None 3XY 4XY 0 -20 Fixed Fixed Fixed Fixed Fixed Fixed 66S None 3X 4X 0 -20 Fixed Fixed Fixed Fixed Fixed Fixed 63AS None 3P 4P 0 -18 Free Free Free Free Free Free 64AS None 3Y 4Y 0 -18 Free Free Free Free Free Free 65AS None 3XY 4XY 0 -18 Free Free Free Free Free Free 66AS None 3X 4X 0 -18 Free Free Free Free Free Free 60SF0.20S None 60S 63AS 0.2 0 Free Free Free Free Free Free 60SF0.40S None 60S 63AS 0.4 0 Free Free Free Free Free Free 60SF0.60S None 60S 63AS 0.6 0 Free Free Free Free Free Free 60SF0.80S None 60S 63AS 0.8 0 Free Free Free Free Free Free 62SF0.20S None 62S 10P 0.2 0 Free Free Free Free Free Free 62SF0.40S None 62S 10P 0.4 0 Free Free Free Free Free Free 62SF0.60S None 62S 10P 0.6 0 Free Free Free Free Free Free 62SF0.80S None 62S 10P 0.8 0 Free Free Free Free Free Free 61SF0.20S None 61S 9P 0.2 0 Free Free Free Free Free Free 61SF0.40S None 61S 9P 0.4 0 Free Free Free Free Free Free 61SF0.60S None 61S 9P 0.6 0 Free Free Free Free Free Free 61SF0.80S None 61S 9P 0.8 0 Free Free Free Free Free Free 60YF0.20S None 60Y 64AS 0.2 0 Free Free Free Free Free Free 60YF0.40S None 60Y 64AS 0.4 0 Free Free Free Free Free Free 60YF0.60S None 60Y 64AS 0.6 0 Free Free Free Free Free Free 60YF0.80S None 60Y 64AS 0.8 0 Free Free Free Free Free Free 62YF0.20S None 62Y 9AP 0.2 0 Free Free Free Free Free Free 62YF0.40S None 62Y 9AP 0.4 0 Free Free Free Free Free Free 62YF0.60S None 62Y 9AP 0.6 0 Free Free Free Free Free Free 62YF0.80S None 62Y 9AP 0.8 0 Free Free Free Free Free Free 61YF0.20S None 61Y 10AP 0.2 0 Free Free Free Free Free Free 61YF0.40S None 61Y 10AP 0.4 0 Free Free Free Free Free Free 61YF0.60S None 61Y 10AP 0.6 0 Free Free Free Free Free Free 61YF0.80S None 61Y 10AP 0.8 0 Free Free Free Free Free Free 61XYF0.20S None 61XY 9BP 0.2 0 Free Free Free Free Free Free 61XYF0.40S None 61XY 9BP 0.4 0 Free Free Free Free Free Free 61XYF0.60S None 61XY 9BP 0.6 0 Free Free Free Free Free Free 61XYF0.80S None 61XY 9BP 0.8 0 Free Free Free Free Free Free 60XYF0.20S None 60XY 65AS 0.2 0 Free Free Free Free Free Free 60XYF0.40S None 60XY 65AS 0.4 0 Free Free Free Free Free Free 60XYF0.60S None 60XY 65AS 0.6 0 Free Free Free Free Free Free 60XYF0.80S None 60XY 65AS 0.8 0 Free Free Free Free Free Free 62XYF0.20S None 62XY 10BP 0.2 0 Free Free Free Free Free Free 62XYF0.40S None 62XY 10BP 0.4 0 Free Free Free Free Free Free 62XYF0.60S None 62XY 10BP 0.6 0 Free Free Free Free Free Free 62XYF0.80S None 62XY 10BP 0.8 0 Free Free Free Free Free Free 61XF0.20S None 61X 10CP 0.2 0 Free Free Free Free Free Free 61XF0.40S None 61X 10CP 0.4 0 Free Free Free Free Free Free 61XF0.60S None 61X 10CP 0.6 0 Free Free Free Free Free Free 61XF0.80S None 61X 10CP 0.8 0 Free Free Free Free Free Free 62XF0.20S None 62X 9CP 0.2 0 Free Free Free Free Free Free 62XF0.40S None 62X 9CP 0.4 0 Free Free Free Free Free Free 62XF0.60S None 62X 9CP 0.6 0 Free Free Free Free Free Free 62XF0.80S None 62X 9CP 0.8 0 Free Free Free Free Free Free 60XF0.20S None 60X 66AS 0.2 0 Free Free Free Free Free Free 60XF0.40S None 60X 66AS 0.4 0 Free Free Free Free Free Free 60XF0.60S None 60X 66AS 0.6 0 Free Free Free Free Free Free 60XF0.80S None 60X 66AS 0.8 0 Free Free Free Free Free Free 21X X-GenXY 2P 3P 0 11.8 Free Free Free Free Free Free 21XY XY-GenXY 2P 3P 0 11.8 Free Free Free Free Free Free 21Y Y-GenXY 2P 3P 0 11.8 Free Free Free Free Free Free 21AY Y-Gen 21S 21X 0.5 0 Free Free Free Free Free Free 22X X-GenXY 2P 3P 0 10.3 Free Free Free Free Free Free 22XY XY-GenXY 2P 3P 0 10.3 Free Free Free Free Free Free 22Y Y-GenXY 2P 3P 0 10.3 Free Free Free Free Free Free 23X X-GenXY 2P 3P 0 8.8 Free Free Free Free Free Free 23XY XY-GenXY 2P 3P 0 8.8 Free Free Free Free Free Free 23Y Y-GenXY 2P 3P 0 8.8 Free Free Free Free Free Free 24X X-GenXY 2P 3P 0 7.3 Free Free Free Free Free Free 24XY XY-GenXY 2P 3P 0 7.3 Free Free Free Free Free Free 24Y Y-GenXY 2P 3P 0 7.3 Free Free Free Free Free Free 25X X-GenXY 2P 3P 0 5.9 Free Free Free Free Free Free 25XY XY-GenXY 2P 3P 0 5.9 Free Free Free Free Free Free 25Y Y-GenXY 2P 3P 0 5.9 Free Free Free Free Free Free 25AY Y-Gen 25S 25X 0.5 0 Free Free Free Free Free Free 3AY Y-Gen 3P 3X 0.5 0 Free Free Free Free Free Free

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 20

26X X-GenXY 2P 3P 0 4.4 Free Free Free Free Free Free 26XY XY-GenXY 2P 3P 0 4.4 Free Free Free Free Free Free 26Y Y-GenXY 2P 3P 0 4.4 Free Free Free Free Free Free 27X X-GenXY 2P 3P 0 2.9 Free Free Free Free Free Free 27XY XY-GenXY 2P 3P 0 2.9 Free Free Free Free Free Free 27Y Y-GenXY 2P 3P 0 2.9 Free Free Free Free Free Free 28X X-GenXY 2P 3P 0 1.4 Free Free Free Free Free Free 28XY XY-GenXY 2P 3P 0 1.4 Free Free Free Free Free Free 28Y Y-GenXY 2P 3P 0 1.4 Free Free Free Free Free Free 29X X-GenXY 3P 4P 0 -1.543 Free Free Free Free Free Free 29XY XY-GenXY 3P 4P 0 -1.543 Free Free Free Free Free Free 29Y Y-GenXY 3P 4P 0 -1.543 Free Free Free Free Free Free 30X X-GenXY 3P 4P 0 -3.381 Free Free Free Free Free Free 30XY XY-GenXY 3P 4P 0 -3.381 Free Free Free Free Free Free 30Y Y-GenXY 3P 4P 0 -3.381 Free Free Free Free Free Free 31X X-GenXY 3P 4P 0 -5.57 Free Free Free Free Free Free 31XY XY-GenXY 3P 4P 0 -5.57 Free Free Free Free Free Free 31Y Y-GenXY 3P 4P 0 -5.57 Free Free Free Free Free Free 32X X-GenXY 3P 4P 0 -8.177 Free Free Free Free Free Free 32XY XY-GenXY 3P 4P 0 -8.177 Free Free Free Free Free Free 32Y Y-GenXY 3P 4P 0 -8.177 Free Free Free Free Free Free 34X X-GenXY 2P 3P 0 12.5 Free Free Free Free Free Free 34XY XY-GenXY 2P 3P 0 12.5 Free Free Free Free Free Free 34Y Y-GenXY 2P 3P 0 12.5 Free Free Free Free Free Free 35X X-GenXY 2P 3P 0 11.05 Free Free Free Free Free Free 35XY XY-GenXY 2P 3P 0 11.05 Free Free Free Free Free Free 35Y Y-GenXY 2P 3P 0 11.05 Free Free Free Free Free Free 36X X-GenXY 2P 3P 0 9.55 Free Free Free Free Free Free 36XY XY-GenXY 2P 3P 0 9.55 Free Free Free Free Free Free 36Y Y-GenXY 2P 3P 0 9.55 Free Free Free Free Free Free 37X X-GenXY 2P 3P 0 8.05 Free Free Free Free Free Free 37XY XY-GenXY 2P 3P 0 8.05 Free Free Free Free Free Free 37Y Y-GenXY 2P 3P 0 8.05 Free Free Free Free Free Free 38X X-GenXY 2P 3P 0 6.6 Free Free Free Free Free Free 38XY XY-GenXY 2P 3P 0 6.6 Free Free Free Free Free Free 38Y Y-GenXY 2P 3P 0 6.6 Free Free Free Free Free Free 39X X-GenXY 2P 3P 0 5.15 Free Free Free Free Free Free 39XY XY-GenXY 2P 3P 0 5.15 Free Free Free Free Free Free 39Y Y-GenXY 2P 3P 0 5.15 Free Free Free Free Free Free 40X X-GenXY 2P 3P 0 3.65 Free Free Free Free Free Free 40XY XY-GenXY 2P 3P 0 3.65 Free Free Free Free Free Free 40Y Y-GenXY 2P 3P 0 3.65 Free Free Free Free Free Free 41X X-GenXY 2P 3P 0 2.15 Free Free Free Free Free Free 41XY XY-GenXY 2P 3P 0 2.15 Free Free Free Free Free Free 41Y Y-GenXY 2P 3P 0 2.15 Free Free Free Free Free Free 42X X-GenXY 2P 3P 0 0.7 Free Free Free Free Free Free 42XY XY-GenXY 2P 3P 0 0.7 Free Free Free Free Free Free 42Y Y-GenXY 2P 3P 0 0.7 Free Free Free Free Free Free 43X X-Gen 2P 2Y 0.5 0 Free Free Free Free Free Free 44X X-Gen 21S 21Y 0.5 0 Free Free Free Free Free Free 45X X-Gen 24S 24Y 0.5 0 Free Free Free Free Free Free 46X X-Gen 25S 25Y 0.5 0 Free Free Free Free Free Free 47X X-Gen 28S 28Y 0.5 0 Free Free Free Free Free Free 48X X-Gen 3P 3Y 0.5 0 Free Free Free Free Free Free 53Y Y-Gen 4P 4X 0.5 0 Free Free Free Free Free Free 54X X-Gen 4P 4Y 0.5 0 Free Free Free Free Free Free 55X X-GenXY 4P 53S 0.4 0 Free Free Free Free Free Free 55XY XY-GenXY 4P 53S 0.4 0 Free Free Free Free Free Free 55Y Y-GenXY 4P 53S 0.4 0 Free Free Free Free Free Free 56X X-GenXY 4P 54S 0.4 0 Free Free Free Free Free Free 56XY XY-GenXY 4P 54S 0.4 0 Free Free Free Free Free Free 56Y Y-GenXY 4P 54S 0.4 0 Free Free Free Free Free Free 57X X-GenXY 55S 54S 0.29 0 Free Free Free Free Free Free 57XY XY-GenXY 55S 54S 0.29 0 Free Free Free Free Free Free 57Y Y-GenXY 55S 54S 0.29 0 Free Free Free Free Free Free 58X X-GenXY 55S 54S 0.6 0 Free Free Free Free Free Free 58XY XY-GenXY 55S 54S 0.6 0 Free Free Free Free Free Free 58Y Y-GenXY 55S 54S 0.6 0 Free Free Free Free Free Free 59X X-GenXY 53S 56S 0.4 0 Free Free Free Free Free Free 59XY XY-GenXY 53S 56S 0.4 0 Free Free Free Free Free Free 59Y Y-GenXY 53S 56S 0.4 0 Free Free Free Free Free Free 60X X-GenXY 3P 4P 0 -12 Free Free Free Free Free Free 60XY XY-GenXY 3P 4P 0 -12 Free Free Free Free Free Free 60Y Y-GenXY 3P 4P 0 -12 Free Free Free Free Free Free 61X X-GenXY 60S 60X 0.4253 0 Free Free Free Free Free Free 61XY XY-GenXY 60S 60X 0.4253 0 Free Free Free Free Free Free 61Y Y-GenXY 60S 60X 0.4253 0 Free Free Free Free Free Free 62X X-GenXY 60S 60Y 0.4253 0 Free Free Free Free Free Free 62XY XY-GenXY 60S 60Y 0.4253 0 Free Free Free Free Free Free 62Y Y-GenXY 60S 60Y 0.4253 0 Free Free Free Free Free Free Steel Material Properties: Steel Modulus Yield Ultimate Member Member Member Member Member Member Material of Stress Stress All. Stress All. Stress Rupture Rupture Bearing Bearing Label Elasticity Fy Fu Hyp. 1 Hyp. 2 Hyp. 1 Hyp. 2 Hyp. 1 Hyp. 2 (MPa) (MPa) (MPa) (MPa) (MPa) (MPa) (MPa) (MPa) (MPa) -------------------------------------------------------------------------------------------- A-36 2e+005 248 399 0 0 0 0 0 0 A572-50 2e+005 345 448 0 0 0 0 0 0

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 21

Bolt Properties: Bolt Bolt Hole Ultimate Default Default Shear Shear Label Diameter Diameter Shear End Bolt Capacity Capacity Capacity Distance Spacing Hyp. 1 Hyp. 2 (cm) (cm) (kN) (cm) (cm) (kN) (kN) -------------------------------------------------------------------- 12 1.27 1.4 40.03 0 0 0 0 16 1.587 1.748 62.72 0 0 0 0 Number Bolts Used By Type: Bolt Number Type Bolts ------------ 12 730 16 504 Angle Groups: Group Group Angle Angle Material Element Group Optimize Allow. Add. Label Description Type Size Type Type Type Group Angle Width For Optimize (cm) ------------------------------------------------------------------------------------------------------------- M-1 MONTANTE ALIM 60X60X6 A572-50 Beam Leg None 0.000 M-2 MONTANTE ALIM 60X60X6 A572-50 Beam Leg None 0.000 M-2A MONTANTE ALIM 60X60X6 A572-50 Beam Leg None 0.000 M-2B MONTANTE ALIM 60X60X6 A572-50 Beam Leg None 0.000 M-2C MONTANTE ALIM 60X60X6 A572-50 Beam Leg None 0.000 M-2D MONTANTE ALIM 60X60X6 A572-50 Beam Leg None 0.000 M-2E MONTANTE ALIM 60X60X6 A572-50 Beam Leg None 0.000 M-3 MONTANTE ALIM 60X60X6 A572-50 Beam Leg None 0.000 M-4 MONTANTE ALIM 80X80X6 A572-50 Beam Leg None 0.000 M-4A MONTANTE ALIM 80X80X6 A572-50 Beam Leg None 0.000 M-4B MONTANTE ALIM 80X80X6 A572-50 Beam Leg None 0.000 M-4C MONTANTE ALIM 80X80X6 A572-50 Beam Leg None 0.000 M-4D MONTANTE ALIM 80X80X6 A572-50 Beam Leg None 0.000 M-4E MONTANTE ALIM 80X80X6 A572-50 Beam Leg None 0.000 M-5 MONTANTE ALIM 80X80X6 A572-50 Beam Leg None 0.000 M-6 MONTANTE ALIM 100X100X6 A572-50 Beam Leg None 0.000 M-7 MONTANTE ALIM 100X100X6 A572-50 Beam Leg None 0.000 M-7A MONTANTE ALIM 100X100X6 A572-50 Beam Leg None 0.000 M-8 MONTANTE ALIM 100X100X7 A572-50 Beam Leg None 0.000 M-8A MONTANTE ALIM 100X100X7 A572-50 Beam Leg None 0.000 M-8B MONTANTE ALIM 100X100X7 A572-50 Beam Leg None 0.000 D-A1 HORIZONTAL ALIM 40X40X4 A572-50 Truss Other None 0.000 D-A DIAGONAL ALIM 45X45X4 A572-50 Truss Other None 0.000 D-1 DIAGONAL ALIM 45X45X4H A572-50 Truss Other None 0.000 D-2 DIAGONAL ALIM 40X40X4H A572-50 Truss Other None 0.000 D-2A DIAGONAL ALIM 40X40X4H A572-50 Truss Other None 0.000 D-2B DIAGONAL ALIM 40X40X4H A572-50 Truss Other None 0.000 D-3 DIAGONAL ALIM 40X40X4H A572-50 Truss Other None 0.000 D-4 DIAGONAL ALIM 45X45X4H A572-50 Truss Other None 0.000 D-4A DIAGONAL ALIM 45X45X4H A572-50 Truss Other None 0.000 D-4B DIAGONAL ALIM 45X45X4H A572-50 Truss Other None 0.000 D-5 DIAGONAL ALIM 45X45X4H A572-50 Truss Other None 0.000 D-6 DIAGONAL ALIM 45X45X4H A572-50 Truss Other None 0.000 D-7 DIAGONAL ALIM 45X45X4 A572-50 Truss Other None 0.000 D-8 DIAGONAL ALIM 45X45X4H A-36 Truss Other None 0.000 D-9 DIAGONAL ALIM 45X45X4H A572-50 Truss Other None 0.000 D-10 DIAGONAL ALIM 50X50X4 A-36 Truss Other None 0.000 D-11 DIAGONAL ALIM 50X50X4 A-36 Truss Other None 0.000 L-1 DIAGONAL LONG. ALIM 40X40X4 A-36 Truss Other None 0.000 L-2 DIAGONAL LONG. ALIM 45X45X4H A572-50 Truss Other None 0.000 L-2A DIAGONAL LONG. ALIM 45X45X4H A572-50 Truss Other None 0.000 L-2B DIAGONAL LONG. ALIM 45X45X4H A572-50 Truss Other None 0.000 L-2C DIAGONAL LONG. ALIM 45X45X4H A572-50 Truss Other None 0.000 L-3 DIAGONAL LONG. ALIM 40X40X4H A572-50 Truss Other None 0.000 L-4 DIAGONAL LONG. ALIM 45X45X4H A572-50 Truss Other None 0.000 L-4A DIAGONAL LONG. ALIM 45X45X4H A572-50 Truss Other None 0.000 L-4B DIAGONAL LONG. ALIM 45X45X4H A572-50 Truss Other None 0.000 L-4C DIAGONAL LONG. ALIM 45X45X4H A572-50 Truss Other None 0.000 L-5 DIAGONAL LONG. ALIM 40X40X4H A572-50 Truss Other None 0.000 H.G.-1 CRUCETA ALIM 40X40X4H A572-50 Beam Other None 0.000 H.G.-2 CRUCETA ALIM 60X60X4 A572-50 Beam Other None 0.000 C.S.-1 CRUCETA ALIM 60X60X4 A572-50 Beam Other None 0.000 C.S.-2 CRUCETA ALIM 60X60X6 A572-50 Beam Other None 0.000 C.INT.-1 CRUCETA ALIM 60X60X4 A572-50 Beam Other None 0.000 C.INT.-2 CRUCETA ALIM 60X60X6 A572-50 Beam Other None 0.000 C.INF.-1 CRUCETA ALIM 60X60X4 A572-50 Beam Other None 0.000 C.INF.-2 CRUCETA ALIM 60X60X6 A572-50 Beam Other None 0.000 H-1 MARCO ALIM L 50X50X4H A572-50 Beam Other None 0.000 H-2 MARCO ALIM L 40X40X4 A-36 Beam Other None 0.000 H-3 MARCO ALIM L 60X60X4 A572-50 Beam Other None 0.000 H-4 MARCO ALIM L 40X40X4 A572-50 Beam Other None 0.000 DH-1 MARCO ALIM L 40X40X4 A572-50 Truss Other None 0.000 H-5 MARCO ALIM L 50X50X4 A572-50 Beam Other None 0.000 H-6 MARCO ALIM L 40X40X4 A-36 Beam Other None 0.000 H-7 MARCO ALIM L 60X60X4 A572-50 Beam Other None 0.000 H-8 MARCO ALIM L 40X40X4 A572-50 Beam Other None 0.000 DH-2 MARCO ALIM L 40X40X4 A572-50 Truss Other None 0.000 H-9 MARCO ALIM L 50X50X4 A572-50 Beam Other None 0.000

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 22

H-10 MARCO ALIM L 40X40X4 A-36 Beam Other None 0.000 H-11 MARCO ALIM L 60X60X4 A572-50 Beam Other None 0.000 H-12 MARCO ALIM L 50X50X4H A572-50 Beam Other None 0.000 DH-3 MARCO ALIM L 40X40X4 A572-50 Truss Other None 0.000 3M-1 CERRAMIENTO ALIM L 100X100X7 A572-50 Beam Other None 0.000 3M-2 CERRAMIENTO ALIM L 100X100X7 A572-50 Beam Other None 0.000 3D-1 CERRAMIENTO 2ALIM 2L 40X40X4 A-36 Truss Other None 0.000 3D-2 CERRAMIENTO ALIS L 1 3/4X3/16 A-36 Truss Other None 0.000 3D-3 CERRAMIENTO ALIM 45X45X4 A-36 Truss Other None 0.000 3H-1 CERRAMIENTO ALIM 50X50X4 A572-50 Beam Other None 0.000 3H-2 CERRAMIENTO ALIM 40X40X4 A-36 Beam Other None 0.000 3R-1 CERRAMIENTO ALIM 40X40X4 A572-50 Beam Redundant None 0.000 3R-2 RIOSTRA ALIM 40X40X4 A572-50 Beam Redundant None 0.000 3R-3 RIOSTRA ALIM 40X40X4 A572-50 Beam Redundant None 0.000 3R-4 CERRAMIENTO ALIM L 40X40X4 A572-50 Beam Redundant None 0.000 3R-5 CERRAMIENTO ALIM 40X40X4H A572-50 Truss Redundant None 0.000 3R-6 RIOSTRA ALIM 35X35X4 A572-50 Beam Redundant None 0.000 0M-1 MONTANTE ALIM L 100X100X7 A572-50 Beam Other None 0.000 0D-1 DIAGONAL ALIS L 2X3/16 A-36 Truss Other None 0.000 0H-1 CERRAMIENTO ALIS L 1 3/4X3/16 A-36 Beam Other None 0.000 0R-1 CERRAMIENTO ALIM 40X40X4 A-36 Beam Redundant None 0.000 0R-2 CERRAMIENTO ALIM 40X40X4 A-36 Beam Redundant None 0.000 0R-3 CERRAMIENTO ALIM 40X40X4 A-36 Beam Redundant None 0.000 PATA-1 EXTENSION ALIM 100X100X7 A572-50 Beam Leg None 0.000 PATA-2 EXTENSION ALIM L 60X60X4 A-36 Truss Other None 0.000 RLT EXTENSION ALIM 35X35X4 A-36 Truss Redundant None 0.000 RD EXTENSION ALIM 35X35X4 A-36 Truss Redundant None 0.000 EXT +3 EXTENSION ALIM 100X100X7 A572-50 Beam Leg None 0.000 EXT +3A EXTENSION ALIM L 60X60X4 A-36 Truss Other None 0.000 EXT +2 EXTENSION ALIM 100X100X7 A572-50 Beam Leg None 0.000 EXT +2A EXTENSION ALIM L 60X60X4 A-36 Truss Other None 0.000 EXT -4 EXTENSION ALIM 100X100X7 A572-50 Beam Leg None 0.000 EXT -4A EXTENSION ALIM L 60X60X4 A-36 Truss Other None 0.000 Sum of Unfactored Dead Load and Drag Areas From Equipment, Input and Calculated: Joint Dead X-Drag Y-Drag Label Load Area Area (kN) (m^2) (m^2) -------------------------------- 1P 0.185 0.331 0.115 2P 0.262 0.491 0.241 3P 0.317 0.440 0.291 4P 0.423 0.565 0.565 5P 0.32 0.579 0.197 6P 0.355 0.504 0.140 7P 0.355 0.504 0.140 8P 0.373 0.528 0.140 9P 0.117 0.183 0.161 10P 0.117 0.161 0.183 9AP 0.118 0.161 0.185 10AP 0.118 0.183 0.162 9BP 0.119 0.185 0.162 10BP 0.119 0.162 0.185 9CP 0.119 0.162 0.185 10CP 0.119 0.185 0.162 1Y 0.185 0.331 0.115 2X 0.262 0.491 0.241 2XY 0.262 0.491 0.241 2Y 0.262 0.491 0.241 3X 0.317 0.440 0.291 3XY 0.317 0.440 0.291 3Y 0.317 0.440 0.291 4X 0.423 0.565 0.565 4XY 0.423 0.565 0.565 4Y 0.423 0.565 0.565 5X 0.32 0.579 0.197 6X 0.355 0.504 0.140 7X 0.355 0.504 0.140 8X 0.373 0.528 0.140 21S 0.217 0.302 0.142 21AS 0.0524 0.075 0.030 22S 0.0902 0.130 0.105 23S 0.0902 0.130 0.105 24S 0.194 0.319 0.164 25S 0.224 0.310 0.150 25AS 0.0524 0.075 0.030 3AS 0.0524 0.075 0.030 26S 0.111 0.155 0.128 27S 0.111 0.155 0.128 28S 0.218 0.350 0.186 29S 0.287 0.384 0.384 30S 0.341 0.453 0.453 31S 0.427 0.581 0.581 32S 0.544 0.670 0.670 34S 0.0616 0.070 0.083 35S 0.0826 0.096 0.117 36S 0.0969 0.113 0.140 37S 0.0826 0.096 0.117 38S 0.0616 0.070 0.083

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 23

39S 0.0968 0.111 0.132 40S 0.111 0.128 0.155 41S 0.0968 0.111 0.132 42S 0.0748 0.084 0.097 43S 0.0422 0.028 0.071 44S 0.0959 0.092 0.149 45S 0.0707 0.062 0.119 46S 0.0959 0.092 0.149 47S 0.0707 0.062 0.119 48S 0.072 0.058 0.109 53S 0.0874 0.113 0.040 54S 0.0874 0.040 0.113 55S 0.0391 0.056 0.016 56S 0.039 0.016 0.056 57S 0.0686 0.084 0.084 58S 0.0389 0.016 0.061 59S 0.039 0.062 0.016 60S 0.177 0.500 0.500 61S 0.15 0.210 0.144 62S 0.15 0.144 0.210 63S 0.189 0.228 0.228 64S 0.189 0.228 0.229 65S 0.189 0.229 0.229 66S 0.189 0.229 0.229 63AS 0.188 0.176 0.176 64AS 0.189 0.176 0.176 65AS 0.189 0.176 0.176 66AS 0.189 0.176 0.176 60SF0.20S 0.192 0.196 0.196 60SF0.40S 0.187 0.192 0.192 60SF0.60S 0.182 0.188 0.188 60SF0.80S 0.178 0.184 0.184 62SF0.20S 0.127 0.159 0.196 62SF0.40S 0.12 0.155 0.187 62SF0.60S 0.114 0.152 0.179 62SF0.80S 0.109 0.148 0.172 61SF0.20S 0.127 0.196 0.159 61SF0.40S 0.12 0.187 0.155 61SF0.60S 0.114 0.179 0.152 61SF0.80S 0.109 0.172 0.148 60YF0.20S 0.192 0.196 0.196 60YF0.40S 0.187 0.192 0.192 60YF0.60S 0.183 0.188 0.188 60YF0.80S 0.178 0.184 0.184 62YF0.20S 0.127 0.159 0.196 62YF0.40S 0.121 0.155 0.188 62YF0.60S 0.115 0.152 0.180 62YF0.80S 0.109 0.148 0.173 61YF0.20S 0.127 0.196 0.159 61YF0.40S 0.121 0.187 0.156 61YF0.60S 0.115 0.179 0.152 61YF0.80S 0.109 0.172 0.149 61XYF0.20S 0.127 0.196 0.159 61XYF0.40S 0.121 0.188 0.156 61XYF0.60S 0.115 0.180 0.152 61XYF0.80S 0.11 0.173 0.149 60XYF0.20S 0.193 0.196 0.196 60XYF0.40S 0.188 0.192 0.192 60XYF0.60S 0.183 0.188 0.188 60XYF0.80S 0.178 0.184 0.184 62XYF0.20S 0.127 0.159 0.196 62XYF0.40S 0.121 0.156 0.188 62XYF0.60S 0.115 0.152 0.180 62XYF0.80S 0.11 0.149 0.173 61XF0.20S 0.127 0.196 0.159 61XF0.40S 0.121 0.188 0.156 61XF0.60S 0.115 0.180 0.152 61XF0.80S 0.11 0.173 0.149 62XF0.20S 0.127 0.159 0.196 62XF0.40S 0.121 0.156 0.188 62XF0.60S 0.115 0.152 0.180 62XF0.80S 0.11 0.149 0.173 60XF0.20S 0.193 0.196 0.196 60XF0.40S 0.188 0.192 0.192 60XF0.60S 0.183 0.188 0.188 60XF0.80S 0.178 0.184 0.184 21X 0.217 0.302 0.142 21XY 0.217 0.302 0.142 21Y 0.217 0.302 0.142 21AY 0.0524 0.075 0.030 22X 0.0902 0.130 0.105 22XY 0.0902 0.130 0.105 22Y 0.0902 0.130 0.105 23X 0.0902 0.130 0.105 23XY 0.0902 0.130 0.105 23Y 0.0902 0.130 0.105 24X 0.194 0.319 0.164 24XY 0.194 0.319 0.164 24Y 0.194 0.319 0.164 25X 0.224 0.310 0.150

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 24

25XY 0.224 0.310 0.150 25Y 0.224 0.310 0.150 25AY 0.0524 0.075 0.030 3AY 0.0524 0.075 0.030 26X 0.111 0.155 0.128 26XY 0.111 0.155 0.128 26Y 0.111 0.155 0.128 27X 0.111 0.155 0.128 27XY 0.111 0.155 0.128 27Y 0.111 0.155 0.128 28X 0.218 0.350 0.186 28XY 0.218 0.350 0.186 28Y 0.218 0.317 0.186 29X 0.287 0.384 0.384 29XY 0.287 0.384 0.384 29Y 0.287 0.384 0.384 30X 0.341 0.453 0.453 30XY 0.341 0.453 0.453 30Y 0.341 0.453 0.453 31X 0.427 0.581 0.581 31XY 0.427 0.581 0.581 31Y 0.427 0.581 0.581 32X 0.544 0.670 0.670 32XY 0.544 0.670 0.670 32Y 0.544 0.670 0.670 34X 0.0616 0.070 0.083 34XY 0.0616 0.070 0.083 34Y 0.0616 0.070 0.083 35X 0.0826 0.096 0.117 35XY 0.0826 0.096 0.117 35Y 0.0826 0.096 0.117 36X 0.0969 0.113 0.140 36XY 0.0969 0.113 0.140 36Y 0.0969 0.113 0.140 37X 0.0826 0.096 0.117 37XY 0.0826 0.096 0.117 37Y 0.0826 0.096 0.117 38X 0.0616 0.070 0.083 38XY 0.0616 0.070 0.083 38Y 0.0616 0.070 0.083 39X 0.0968 0.111 0.132 39XY 0.0968 0.111 0.132 39Y 0.0968 0.111 0.132 40X 0.111 0.128 0.155 40XY 0.111 0.128 0.155 40Y 0.111 0.128 0.155 41X 0.0968 0.111 0.132 41XY 0.0968 0.111 0.132 41Y 0.0968 0.111 0.132 42X 0.0748 0.084 0.097 42XY 0.0748 0.084 0.097 42Y 0.0748 0.084 0.097 43X 0.0422 0.028 0.071 44X 0.0959 0.092 0.149 45X 0.0707 0.062 0.119 46X 0.0959 0.092 0.149 47X 0.0707 0.062 0.119 48X 0.072 0.058 0.109 53Y 0.0874 0.113 0.040 54X 0.0874 0.040 0.113 55X 0.0391 0.056 0.016 55XY 0.0391 0.056 0.016 55Y 0.0391 0.056 0.016 56X 0.039 0.016 0.056 56XY 0.039 0.016 0.056 56Y 0.039 0.016 0.056 57X 0.0686 0.084 0.084 57XY 0.0686 0.084 0.084 57Y 0.0686 0.084 0.084 58X 0.0389 0.016 0.061 58XY 0.0389 0.016 0.061 58Y 0.0389 0.016 0.061 59X 0.039 0.062 0.016 59XY 0.039 0.062 0.016 59Y 0.039 0.062 0.016 60X 0.177 0.500 0.500 60XY 0.177 0.500 0.500 60Y 0.177 0.500 0.500 61X 0.15 0.210 0.144 61XY 0.15 0.210 0.144 61Y 0.15 0.210 0.144 62X 0.15 0.144 0.210 62XY 0.15 0.144 0.210 62Y 0.15 0.144 0.210 Total 35.2 47.457 40.591

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 25

Unadjusted Dead Load and Drag Areas by Section: Section Unfactored X-Drag Y-Drag X-Drag Y-Drag Label Dead Load Area All Area All Area Face Area Face (kN) (m^2) (m^2) (m^2) (m^2) --------------------------------------------------------- A 1.612 2.487 0.954 1.244 0.507 B 2.416 3.113 1.717 1.385 0.613 C 4.516 5.830 4.515 2.398 1.785 D 5.416 6.864 5.345 2.855 2.081 E 6.012 7.213 7.183 2.808 2.793 F 2.419 2.779 2.779 1.078 1.078 g 2.853 2.837 2.838 0.834 0.834 H 9.978 12.463 12.473 4.226 4.233 Total 35.221 43.587 37.805 16.827 13.924 Manually Input Dead Loads and Drag Areas: Load Attach Vertical Transverse Longitudinal Point Point Dead Wind Wind Label Load Area Area (kN) (m^2) (m^2) ---------------------------------------------- V-1 1P 0.000 0.000 0.051 V-2 1Y 0.000 0.000 0.051 V-3 2P 0.000 0.049 0.084 V-4 2X 0.000 0.049 0.084 V-5 2XY 0.000 0.049 0.084 V-6 2Y 0.000 0.049 0.084 V-7 5P 0.000 0.049 0.051 V-8 5X 0.000 0.049 0.051 V-9 6P 0.000 0.000 0.033 V-10 6X 0.000 0.000 0.033 V-11 21S 0.000 0.000 0.033 V-12 21X 0.000 0.000 0.033 V-13 21XY 0.000 0.000 0.033 V-14 21Y 0.000 0.000 0.033 V-15 24S 0.000 0.000 0.033 V-16 24X 0.000 0.000 0.033 V-17 24XY 0.000 0.000 0.033 V-18 24Y 0.000 0.000 0.033 V-19 25S 0.000 0.000 0.033 V-20 25X 0.000 0.000 0.033 V-21 25XY 0.000 0.000 0.033 V-22 25Y 0.000 0.000 0.033 V-23 7P 0.000 0.000 0.033 V-24 7X 0.000 0.000 0.033 V-25 28S 0.000 0.000 0.033 V-26 28X 0.000 0.000 0.033 V-27 28XY 0.000 0.000 0.033 V-28 3P 0.000 0.027 0.060 V-29 3X 0.000 0.027 0.060 V-30 3XY 0.000 0.027 0.060 V-31 3Y 0.000 0.027 0.060 V-32 8P 0.000 0.000 0.033 V-33 8X 0.000 0.000 0.033 V-34 29S 0.000 0.027 0.027 V-35 29X 0.000 0.027 0.027 V-36 29XY 0.000 0.027 0.027 V-37 29Y 0.000 0.027 0.027 V-38 30S 0.000 0.027 0.027 V-39 30X 0.000 0.027 0.027 V-40 30XY 0.000 0.027 0.027 V-41 30Y 0.000 0.027 0.027 V-42 31S 0.000 0.075 0.075 V-43 31X 0.000 0.075 0.075 V-44 31XY 0.000 0.075 0.075 V-45 31Y 0.000 0.075 0.075 V-46 32S 0.000 0.048 0.048 V-47 32X 0.000 0.048 0.048 V-48 32XY 0.000 0.048 0.048 V-49 32Y 0.000 0.048 0.048 V-54 4P 0.000 0.100 0.100 V-55 4X 0.000 0.100 0.100 V-56 4XY 0.000 0.100 0.100 V-57 4Y 0.000 0.100 0.100 V-74 60S 0.000 0.320 0.320 V-75 60X 0.000 0.320 0.320 V-76 60XY 0.000 0.320 0.320 V-77 60Y 0.000 0.320 0.320 Total 0.000 2.786 3.870

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 26

*** Loads Data Loads from file: d:\my documents\td1_definitivo\revision c\cerramiento +12\extensiones\viento con un circuito.lca Insulator dead and wind loads are already included in the point loads printed below. Loading Method Parameters: Structure Height Summary (used for calculating wind/ice adjust with height): Z of ground (lowest joint) -20.00 (m) Ground elevation shift 0.00 (m) Z of ground with shift -20.00 (m) Z of structure top (highest joint) 14.85 (m) Structure height 34.85 (m) Structure height above ground 34.85 (m) Vector Load Cases: Load Case Dead Wind SF for SF for SF for SF For Point Wind/Ice Trans. Longit. Ice Ice Joint Description Load Area Steel Poles Guys Insuls. Found. Loads Model Wind Wind Thick. Density Displ. Factor Factor Tubular Arms and Pressure Pressure and Towers Cables (Pa) (Pa) (cm) (N/m^3) ------------------------------------------------------------------------------------------------------------------------------------- I 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 2256 0 0.000 0.000 IA 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 5 loads Wind on Face 2256 0 0.000 0.000 II 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 2256 0.000 0.000 IIA 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 5 loads Wind on Face 0 2256 0.000 0.000 III 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 1595 1595 0.000 0.000 IIIA 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 5 loads Wind on Face 1595 1595 0.000 0.000 IV HG1 1C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 5 loads Wind on Face 0 0 0.000 0.000 IV HG2 1C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 5 loads Wind on Face 0 0 0.000 0.000 IV COND 3 1C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 5 loads Wind on Face 0 0 0.000 0.000 IV COND 4 1C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 5 loads Wind on Face 0 0 0.000 0.000 IV COND 5 1C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 5 loads Wind on Face 0 0 0.000 0.000 IV HG1yHG2 2C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 IV HG1yCOND4 2C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 IV HG1yCOND6 2C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 IV HG1yCOND8 2C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 IV COND3yCOND4 2C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 IV COND3yCOND6 2C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 IV COND3yCOND8 2C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 IV COND5yCOND6 2C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 IV COND5yCOND8 2C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 IV COND7yCOND8 2C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 IV HG1 2C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 IV COND3 2C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 IV COND5 2C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 IV COND7 2C 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 V 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 VA 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 5 loads Wind on Face 0 0 0.000 0.000 VIg 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 4 loads Wind on Face 0 0 0.000 0.000 VIfs 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 4 loads Wind on Face 0 0 0.000 0.000 VIfi 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 4 loads Wind on Face 0 0 0.000 0.000 VIg2 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 VIfs2 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 VIfi2 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 VIIg 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 4 loads Wind on Face 0 0 0.000 0.000 VIIfs 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 4 loads Wind on Face 0 0 0.000 0.000 VIIfi 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 4 loads Wind on Face 0 0 0.000 0.000 VIIg2 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 VIIfs2 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 VIIfi2 1.0000 1.0000 1.00000 1.0000 1.0000 1.0000 8 loads Wind on Face 0 0 0.000 0.000 Point Loads for Load Case "I": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 4812 3252 1471.5 5X 4812 4414.5 1471.5 6P 16363 10418.2 1471.5 6X 16363 10418.2 1471.5 7P 16363 10418.2 1471.5 7X 16363 10418.2 1471.5 8P 16363 10418.2 1471.5 8X 16363 10418.2 1471.5 Point Loads for Load Case "IA": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 4812 3252 1471.5 5X 4812 4414.5 1471.5 6X 16363 10418.2 1471.5 7X 16363 10418.2 1471.5 8X 16363 10418.2 1471.5

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 27

Point Loads for Load Case "II": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 4120 338.5 1765.8 5X 4120 427 1765.8 6P 14258.8 1236.06 3369.74 6X 14258.8 1236.06 3369.74 7P 14258.8 1236.06 3369.74 7X 14258.8 1236.06 3369.74 8P 14258.8 1236.06 3369.74 8X 14258.8 1236.06 3369.74 Point Loads for Load Case "IIA": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 4120 338.5 1765.8 5X 4120 427 1765.8 6X 14258.8 1236.06 3369.74 7X 14258.8 1236.06 3369.74 8X 14258.8 1236.06 3369.74 Point Loads for Load Case "III": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 4811.8 1765.8 1765.8 5X 4811.9 2383.8 1765.8 6P 16363 5841.85 3237.3 6X 16363 5841.85 3237.3 7P 16363 5841.85 3237.3 7X 16363 5841.85 3237.3 8P 16363 5841.85 3237.3 8X 16363 5841.85 3237.3 Point Loads for Load Case "IIIA": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 4811.8 1765.8 1765.8 5X 4811.9 2383.8 1765.8 6X 16363 5841.85 3237.3 7X 16363 5841.85 3237.3 8X 16363 5841.85 3237.3 Point Loads for Load Case "IV HG1 1C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 153 8652.4 6X 11407.1 847.6 0 7X 11407.1 847.6 0 8X 11407.1 847.6 0 Point Loads for Load Case "IV HG2 1C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 117.7 6992.6 5X 3296.16 306 0 6X 11407.1 847.6 0 7X 11407.1 847.6 0 8X 11407.1 847.6 0

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 28

Point Loads for Load Case "IV COND 3 1C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 306 0 6X 11407.1 423.792 24450.4 7X 11407.1 847.6 0 8X 11407.1 847.6 0 Point Loads for Load Case "IV COND 4 1C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 306 0 6X 11407.1 847.6 0 7X 11407.1 423.792 24450.4 8X 11407.1 847.6 0 Point Loads for Load Case "IV COND 5 1C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 306 0 6X 11407.1 847.6 0 7X 11407.1 847.6 0 8X 11407.1 423.792 24450.4 Point Loads for Load Case "IV HG1yHG2 2C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 117.7 6992.6 5X 3296.16 153 8652.4 6P 11407.1 847.6 0 6X 11407.1 847.6 0 7P 11407.1 847.6 0 7X 11407.1 847.6 0 8P 11407.1 847.6 0 8X 11407.1 847.6 0 Point Loads for Load Case "IV HG1yCOND4 2C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 153 8652.4 6P 11407.1 423.792 24450.4 6X 11407.1 847.6 0 7P 11407.1 847.6 0 7X 11407.1 847.6 0 8P 11407.1 847.6 0 8X 11407.1 847.6 0 Point Loads for Load Case "IV HG1yCOND6 2C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 153 8652.4 6P 11407.1 847.6 0 6X 11407.1 847.6 0 7P 11407.1 423.792 24450.4 7X 11407.1 847.6 0 8P 11407.1 847.6 0 8X 11407.1 847.6 0

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 29

Point Loads for Load Case "IV HG1yCOND8 2C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 153 8652.4 6P 11407.1 847.6 0 6X 11407.1 847.6 0 7P 11407.1 847.6 0 7X 11407.1 847.6 0 8P 11407.1 423.792 24450.4 8X 11407.1 847.6 0 Point Loads for Load Case "IV COND3yCOND4 2C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 306.1 0 6P 11407.1 423.792 24450.4 6X 11407.1 423.792 24450.4 7P 11407.1 847.6 0 7X 11407.1 847.6 0 8P 11407.1 847.6 0 8X 11407.1 847.6 0 Point Loads for Load Case "IV COND3yCOND6 2C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 306.1 0 6P 11407.1 847.6 0 6X 11407.1 423.792 24450.4 7P 11407.1 423.792 24450.4 7X 11407.1 847.6 0 8P 11407.1 847.6 0 8X 11407.1 847.6 0 Point Loads for Load Case "IV COND3yCOND8 2C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 306.1 0 6P 11407.1 847.6 0 6X 11407.1 423.792 24450.4 7P 11407.1 847.6 0 7X 11407.1 847.6 0 8P 11407.1 423.792 24450.4 8X 11407.1 847.6 0 Point Loads for Load Case "IV COND5yCOND6 2C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 306.1 0 6P 11407.1 847.6 0 6X 11407.1 847.6 0 7P 11407.1 423.792 24450.4 7X 11407.1 423.792 24450.4 8P 11407.1 847.6 0 8X 11407.1 847.6 0

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 30

Point Loads for Load Case "IV COND5yCOND8 2C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 306.1 0 6P 11407.1 847.6 0 6X 11407.1 847.6 0 7P 11407.1 847.6 0 7X 11407.1 423.792 24450.4 8P 11407.1 423.792 24450.4 8X 11407.1 847.6 0 Point Loads for Load Case "IV COND7yCOND8 2C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 306.1 0 6P 11407.1 847.6 0 6X 11407.1 847.6 0 7P 11407.1 847.6 0 7X 11407.1 847.6 0 8P 11407.1 423.792 24450.4 8X 11407.1 423.792 24450.4 Point Loads for Load Case "IV HG1 2C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 153 8652.4 6P 11407.1 847.6 0 6X 11407.1 847.6 0 7P 11407.1 847.6 0 7X 11407.1 847.6 0 8P 11407.1 847.6 0 8X 11407.1 847.6 0 Point Loads for Load Case "IV COND3 2C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 306.1 0 6P 11407.1 847.6 0 6X 11407.1 423.792 24450.4 7P 11407.1 847.6 0 7X 11407.1 847.6 0 8P 11407.1 847.6 0 8X 11407.1 847.6 0 Point Loads for Load Case "IV COND5 2C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 306.1 0 6P 11407.1 847.6 0 6X 11407.1 847.6 0 7P 11407.1 847.6 0 7X 11407.1 423.792 24450.4 8P 11407.1 847.6 0 8X 11407.1 847.6 0 Point Loads for Load Case "IV COND7 2C": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 31

(N) (N) (N) ----------------------------------------------- 5P 3296.16 247.2 0 5X 3296.16 306.1 0 6P 11407.1 847.6 0 6X 11407.1 847.6 0 7P 11407.1 847.6 0 7X 11407.1 847.6 0 8P 11407.1 847.6 0 8X 11407.1 423.792 24450.4 Point Loads for Load Case "V": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 23.6 1389.1 5X 3296.16 35.32 2213.14 6P 11407.1 82.4 4920.7 6X 11407.1 82.4 4920.7 7P 11407.1 82.4 4920.7 7X 11407.1 82.4 4920.7 8P 11407.1 82.4 4920.7 8X 11407.1 82.4 4920.7 Point Loads for Load Case "VA": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 3296.16 23.6 1389.1 5X 3296.16 35.32 2213.14 6X 11407.1 82.4 4920.7 7X 11407.1 82.4 4920.7 8X 11407.1 82.4 4920.7 Point Loads for Load Case "VIg": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5X 13124.8 150.1 8572 6X 16160 1200.7 0 7X 16160 1200.7 0 8X 16160 1200.7 0 Point Loads for Load Case "VIfs": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5X 4669.6 433.6 0 6X 32453.4 416.9 24248.4 7X 16160 1200.7 0 8X 16160 1200.7 0 Point Loads for Load Case "VIfi": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5X 4669.6 433.6 0 6X 16160 1200.7 0 7X 16160 1200.7 0 8X 32453.4 416.9 24248.4 Point Loads for Load Case "VIg2": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 4669.6 350.2 0 5X 13124.8 150.1 8572 6P 16160 1200.7 0 6X 16160 1200.7 0 7P 16160 1200.7 0 7X 16160 1200.7 0 8P 16160 1200.7 0 8X 16160 1200.7 0

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 32

Point Loads for Load Case "VIfs2": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 4669.6 350.2 0 5X 4669.6 433.6 0 6P 16160 1200.7 0 6X 32453.4 416.9 24248.4 7P 16160 1200.7 0 7X 16160 1200.7 0 8P 16160 1200.7 0 8X 16160 1200.7 0 Point Loads for Load Case "VIfi2": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 4669.6 350.2 0 5X 4669.6 433.6 0 6P 16160 1200.7 0 6X 16160 1200.7 0 7P 16160 1200.7 0 7X 16160 1200.7 0 8P 16160 1200.7 0 8X 32453.4 416.9 24248.4 Point Loads for Load Case "VIIg": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5X 13508.4 433.6 0 6X 16160 1200.7 0 7X 16160 1200.7 0 8X 16160 1200.7 0 Point Loads for Load Case "VIIfs": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5X 4669.6 433.6 0 6X 36489.3 1200.7 0 7X 16160 1200.7 0 8X 16160 1200.7 0 Point Loads for Load Case "VIIfi": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5X 4669.6 433.6 0 6X 16160 1200.7 0 7X 16160 1200.7 0 8X 36489.3 1200.7 0 Point Loads for Load Case "VIIg2": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 4669.6 350.12 0 5X 13508.4 433.6 0 6P 16160 1200.7 0 6X 16160 1200.7 0 7P 16160 1200.7 0 7X 16160 1200.7 0 8P 16160 1200.7 0 8X 16160 1200.7 0

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 33

Point Loads for Load Case "VIIfs2": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 4669.6 350.2 0 5X 4669.6 433.6 0 6P 16160 1200.7 0 6X 36489.3 1200.7 0 7P 16160 1200.7 0 7X 16160 1200.7 0 8P 16160 1200.7 0 8X 16160 1200.7 0 Point Loads for Load Case "VIIfi2": Joint Vertical Transverse Longitudinal Load Label Load Load Load Comment (N) (N) (N) ----------------------------------------------- 5P 4669.6 350.2 0 5X 4669.6 433.6 0 6P 16160 1200.7 0 6X 16160 1200.7 0 7P 16160 1200.7 0 7X 16160 1200.7 0 8P 16160 1200.7 0 8X 36489.3 1200.7 0 Joint Support Reactions for Load Case "I": Joint X X Y Y Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max. Label Force Usage Force Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage (kN) % (kN) % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % % ------------------------------------------------------------------------------------------------------------------ 63S -29.01 0.0 -32.87 0.0 313.96 0.0 0.0 317.00 0.0 -2.00 0.0 2.8 0.0 0.06 0.0 0.0 64S 23.00 0.0 -26.87 0.0 249.63 0.0 0.0 252.12 0.0 -1.42 0.0 -2.2 0.0 -0.07 0.0 0.0 65S -21.83 0.0 -28.10 0.0 -237.09 0.0 0.0 239.74 0.0 -1.12 0.0 2.0 0.0 -0.08 0.0 0.0 66S 16.07 0.0 -22.35 0.0 -174.03 0.0 0.0 176.19 0.0 -0.53 0.0 -1.5 0.0 0.09 0.0 0.0 Joint Support Reactions for Load Case "IA": Joint X X Y Y Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max. Label Force Usage Force Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage (kN) % (kN) % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % % ------------------------------------------------------------------------------------------------------------------ 63S -17.00 0.0 -24.02 0.0 195.39 0.0 0.0 197.59 0.0 -0.79 0.0 1.8 0.0 0.07 0.0 0.0 64S 15.18 0.0 -18.13 0.0 153.10 0.0 0.0 154.92 0.0 -0.62 0.0 -1.2 0.0 -0.06 0.0 0.0 65S -13.77 0.0 -19.30 0.0 -139.97 0.0 0.0 141.97 0.0 -0.34 0.0 1.0 0.0 -0.08 0.0 0.0 66S 8.23 0.0 -17.50 0.0 -98.83 0.0 0.0 100.71 0.0 0.26 0.0 -0.8 0.0 0.09 0.0 0.0 Joint Support Reactions for Load Case "II": Joint X X Y Y Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max. Label Force Usage Force Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage (kN) % (kN) % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % % ------------------------------------------------------------------------------------------------------------------ 63S -22.05 0.0 -18.74 0.0 201.66 0.0 0.0 203.73 0.0 -1.74 0.0 1.2 0.0 -0.05 0.0 0.0 64S -13.30 0.0 7.41 0.0 -81.01 0.0 0.0 82.43 0.0 0.65 0.0 -0.1 0.0 -0.07 0.0 0.0 65S -17.26 0.0 -11.53 0.0 -124.66 0.0 0.0 126.38 0.0 -0.95 0.0 0.3 0.0 0.06 0.0 0.0 66S -17.81 0.0 14.33 0.0 156.48 0.0 0.0 158.14 0.0 1.38 0.0 0.7 0.0 0.05 0.0 0.0 Joint Support Reactions for Load Case "IIA": Joint X X Y Y Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max. Label Force Usage Force Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage (kN) % (kN) % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % % ----------------------------------------------------------------------------------------------------------------- 63S -13.69 0.0 -16.74 0.0 137.62 0.0 0.0 139.31 0.0 -0.71 0.0 0.9 0.0 -0.02 0.0 0.0 64S -12.13 0.0 9.24 0.0 -94.95 0.0 0.0 96.17 0.0 0.71 0.0 0.4 0.0 -0.07 0.0 0.0 65S -15.36 0.0 -7.04 0.0 -81.79 0.0 0.0 83.51 0.0 -0.64 0.0 -0.3 0.0 0.06 0.0 0.0 66S -19.15 0.0 9.71 0.0 148.81 0.0 0.0 150.35 0.0 1.74 0.0 0.5 0.0 0.07 0.0 0.0 Joint Support Reactions for Load Case "III": Joint X X Y Y Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max. Label Force Usage Force Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage (kN) % (kN) % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % % ------------------------------------------------------------------------------------------------------------------ 63S -30.14 0.0 -30.32 0.0 299.68 0.0 0.0 302.72 0.0 -2.13 0.0 2.2 0.0 0.01 0.0 0.0 64S 2.00 0.0 -8.77 0.0 67.04 0.0 0.0 67.64 0.0 -0.15 0.0 -1.2 0.0 -0.09 0.0 0.0 65S -24.63 0.0 -24.81 0.0 -222.59 0.0 0.0 225.32 0.0 -1.24 0.0 1.3 0.0 -0.01 0.0 0.0 66S -3.19 0.0 -3.59 0.0 8.33 0.0 0.0 9.62 0.0 0.70 0.0 -0.3 0.0 0.09 0.0 0.0 Joint Support Reactions for Load Case "IIIA": Joint X X Y Y Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max. Label Force Usage Force Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage (kN) % (kN) % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % % ------------------------------------------------------------------------------------------------------------------

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 34

63S -18.79 0.0 -24.87 0.0 202.21 0.0 0.0 204.60 0.0 -0.89 0.0 1.6 0.0 0.03 0.0 0.0 64S -0.17 0.0 -3.50 0.0 17.76 0.0 0.0 18.10 0.0 0.17 0.0 -0.4 0.0 -0.08 0.0 0.0 65S -19.57 0.0 -17.04 0.0 -146.35 0.0 0.0 148.64 0.0 -0.70 0.0 0.4 0.0 -0.01 0.0 0.0 66S -7.71 0.0 -4.57 0.0 36.08 0.0 0.0 37.17 0.0 1.28 0.0 -0.2 0.0 0.10 0.0 0.0 Joint Support Reactions for Load Case "IV HG1 1C": Joint X X Y Y Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max. Label Force Usage Force Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage (kN) % (kN) % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % % --------------------------------------------------------------------------------------------------------------- 63S -1.61 0.0 -9.56 0.0 56.11 0.0 0.0 56.94 0.0 -0.01 0.0 0.8 0.0 0.03 0.0 0.0 64S 1.87 0.0 3.26 0.0 -18.83 0.0 0.0 19.20 0.0 0.04 0.0 0.6 0.0 0.00 0.0 0.0 65S -2.79 0.0 1.03 0.0 -5.79 0.0 0.0 6.51 0.0 -0.23 0.0 -0.3 0.0 -0.00 0.0 0.0 66S -8.52 0.0 1.88 0.0 67.53 0.0 0.0 68.09 0.0 1.13 0.0 0.3 0.0 0.02 0.0 0.0 Joint Support Reactions for Load Case "IV HG2 1C": Joint X X Y Y Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max. Label Force Usage Force Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage (kN) % (kN) % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % % --------------------------------------------------------------------------------------------------------------- 63S -7.44 0.0 -3.62 0.0 55.52 0.0 0.0 56.14 0.0 -0.68 0.0 0.2 0.0 -0.00 0.0 0.0 64S -3.96 0.0 -2.68 0.0 -18.24 0.0 0.0 18.86 0.0 0.71 0.0 -0.1 0.0 -0.02 0.0 0.0 65S 3.04 0.0 -4.91 0.0 -6.37 0.0 0.0 8.60 0.0 0.42 0.0 0.4 0.0 -0.02 0.0 0.0 66S -2.69 0.0 7.82 0.0 68.11 0.0 0.0 68.60 0.0 0.47 0.0 1.0 0.0 -0.00 0.0 0.0 Joint Support Reactions for Load Case "IV COND 3 1C": Joint X X Y Y Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max. Label Force Usage Force Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage (kN) % (kN) % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % % ----------------------------------------------------------------------------------------------------------------- 63S -2.49 0.0 -15.45 0.0 93.45 0.0 0.0 94.75 0.0 -0.09 0.0 1.4 0.0 0.03 0.0 0.0 64S 0.76 0.0 9.35 0.0 -58.60 0.0 0.0 59.35 0.0 0.13 0.0 1.2 0.0 0.01 0.0 0.0 65S -8.46 0.0 0.08 0.0 -42.46 0.0 0.0 43.29 0.0 -0.84 0.0 -0.2 0.0 0.01 0.0 0.0 66S -14.41 0.0 3.03 0.0 106.62 0.0 0.0 107.63 0.0 1.76 0.0 0.4 0.0 0.04 0.0 0.0 Joint Support Reactions for Load Case "IV COND 4 1C": Joint X X Y Y Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max. Label Force Usage Force Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage (kN) % (kN) % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % % ----------------------------------------------------------------------------------------------------------------- 63S -2.50 0.0 -14.14 0.0 79.57 0.0 0.0 80.85 0.0 0.07 0.0 1.2 0.0 0.02 0.0 0.0 64S 0.80 0.0 8.05 0.0 -44.22 0.0 0.0 44.95 0.0 -0.04 0.0 0.9 0.0 -0.00 0.0 0.0 65S -8.50 0.0 1.35 0.0 -28.80 0.0 0.0 30.06 0.0 -0.68 0.0 -0.5 0.0 0.02 0.0 0.0 66S -14.41 0.0 1.76 0.0 92.47 0.0 0.0 93.60 0.0 1.59 0.0 0.1 0.0 0.05 0.0 0.0 Joint Support Reactions for Load Case "IV COND 5 1C": Joint X X Y Y Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max. Label Force Usage Force Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage (kN) % (kN) % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % % ----------------------------------------------------------------------------------------------------------------- 63S -2.26 0.0 -13.06 0.0 65.85 0.0 0.0 67.17 0.0 0.25 0.0 0.9 0.0 0.02 0.0 0.0 64S 1.08 0.0 6.96 0.0 -30.00 0.0 0.0 30.82 0.0 -0.23 0.0 0.6 0.0 -0.01 0.0 0.0 65S -8.79 0.0 2.85 0.0 -14.97 0.0 0.0 17.59 0.0 -0.55 0.0 -0.8 0.0 0.03 0.0 0.0 66S -14.65 0.0 0.26 0.0 78.14 0.0 0.0 79.50 0.0 1.45 0.0 -0.2 0.0 0.06 0.0 0.0 Joint Support Reactions for Load Case "IV HG1yHG2 2C": Joint X X Y Y Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max. Label Force Usage Force Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage (kN) % (kN) % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % % ----------------------------------------------------------------------------------------------------------------- 63S -10.09 0.0 -11.45 0.0 123.11 0.0 0.0 124.06 0.0 -1.14 0.0 1.2 0.0 0.00 0.0 0.0 64S -1.06 0.0 2.31 0.0 -25.62 0.0 0.0 25.75 0.0 0.30 0.0 0.3 0.0 -0.00 0.0 0.0 65S -3.81 0.0 -5.18 0.0 -56.01 0.0 0.0 56.37 0.0 -0.52 0.0 0.6 0.0 -0.00 0.0 0.0 66S -7.14 0.0 8.39 0.0 91.75 0.0 0.0 92.41 0.0 0.89 0.0 0.9 0.0 0.00 0.0 0.0 Joint Support Reactions for Load Case "IV HG1yCOND4 2C": Joint X X Y Y Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max. Label Force Usage Force Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage (kN) % (kN) % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % % ----------------------------------------------------------------------------------------------------------------- 63S -15.79 0.0 -12.45 0.0 159.98 0.0 0.0 161.24 0.0 -1.76 0.0 1.2 0.0 -0.01 0.0 0.0 64S -6.99 0.0 3.50 0.0 -64.91 0.0 0.0 65.38 0.0 0.95 0.0 0.3 0.0 -0.02 0.0 0.0 65S -4.66 0.0 -11.03 0.0 -93.15 0.0 0.0 93.92 0.0 -0.59 0.0 1.1 0.0 -0.01 0.0 0.0 66S -8.22 0.0 14.45 0.0 131.32 0.0 0.0 132.37 0.0 0.98 0.0 1.5 0.0 -0.01 0.0 0.0 Joint Support Reactions for Load Case "IV HG1yCOND6 2C": Joint X X Y Y Z Comp. Uplift Result. Result. X X-M. Y Y-M. Z Z-M. Max. Label Force Usage Force Usage Force Usage Usage Force Usage Moment Usage Moment Usage Moment Usage Usage (kN) % (kN) % (kN) % % (kN) % (kN-m) % (kN-m) % (kN-m) % % ----------------------------------------------------------------------------------------------------------------- 63S -15.81 0.0 -11.15 0.0 146.23 0.0 0.0 147.50 0.0 -1.61 0.0 0.9 0.0 -0.02 0.0 0.0 64S -6.97 0.0 2.21 0.0 -50.67 0.0 0.0 51.19 0.0 0.79 0.0 0.1 0.0 -0.03 0.0 0.0 65S -4.68 0.0 -9.74 0.0 -79.36 0.0 0.0 80.09 0.0 -0.43 0.0 0.9 0.0 -0.00 0.0 0.0 66S -8.20 0.0 13.16 0.0 117.03 0.0 0.0 118.05 0.0 0.82 0.0 1.2 0.0 0.00 0.0 0.0

TD3 SIEPAC-L1-GE-S-MC-2602 Rev A PAG. 35